Jan . 14, 2025 09:37

Back to list

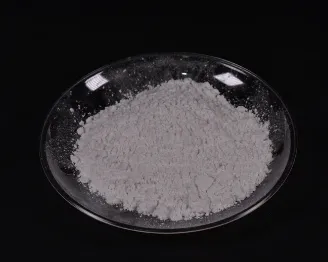

calcined mica powder

When crafting handmade soap, artisans often turn to mica powder for adding vibrant colors. However, understanding the proper use of mica in soap-making is essential to achieving the best results while ensuring safety. Mica powders, typically composed of the mineral mica coated with pigments, offer a shimmering effect that is highly coveted in the cosmetic world.

Expert soap makers often advise against using mica in large batches when new to the craft. The interaction between mica and various soap bases can lead to unexpected results, such as color morphing or fading, particularly under high pH conditions prevalent in cold process soaps. This phenomenon is known as “color morphing, where a vibrant hue can turn muddy or pastel if not correctly compensated for. Furthermore, ensuring the soap’s curing environment is stable is paramount. Sudden temperature changes or humidity can affect the final presentation of mica colors. A cool, dry area is ideal, supporting both the curing of the soap and the stability of the mica pigmentation. The credibility of mica usage in soap extends beyond personal crafting. The beauty industry widely recognizes and accepts mica as a safe and effective coloring agent. Esteemed entities, such as the U.S. Food and Drug Administration (FDA) and the European Chemicals Agency (ECHA), regulate and approve mica powders for cosmetic applications when used appropriately. This authoritative endorsement underlines mica’s reliability and trustworthiness in skin-contact products. Adhering to best practices, such as using verified cosmetic-grade micas and adopting suitable mixing techniques, enhances both the aesthetic and safety of handmade soaps. Whether for personal enjoyment or commercial sale, understanding the nuances of mica use fosters not only creativity but also the integrity of the soap-making craft. Respecting these parameters ensures the final product is as pleasing visually as it is safe for consumer use, culminating in a product that reflects both artisanal expertise and a commitment to quality.

Expert soap makers often advise against using mica in large batches when new to the craft. The interaction between mica and various soap bases can lead to unexpected results, such as color morphing or fading, particularly under high pH conditions prevalent in cold process soaps. This phenomenon is known as “color morphing, where a vibrant hue can turn muddy or pastel if not correctly compensated for. Furthermore, ensuring the soap’s curing environment is stable is paramount. Sudden temperature changes or humidity can affect the final presentation of mica colors. A cool, dry area is ideal, supporting both the curing of the soap and the stability of the mica pigmentation. The credibility of mica usage in soap extends beyond personal crafting. The beauty industry widely recognizes and accepts mica as a safe and effective coloring agent. Esteemed entities, such as the U.S. Food and Drug Administration (FDA) and the European Chemicals Agency (ECHA), regulate and approve mica powders for cosmetic applications when used appropriately. This authoritative endorsement underlines mica’s reliability and trustworthiness in skin-contact products. Adhering to best practices, such as using verified cosmetic-grade micas and adopting suitable mixing techniques, enhances both the aesthetic and safety of handmade soaps. Whether for personal enjoyment or commercial sale, understanding the nuances of mica use fosters not only creativity but also the integrity of the soap-making craft. Respecting these parameters ensures the final product is as pleasing visually as it is safe for consumer use, culminating in a product that reflects both artisanal expertise and a commitment to quality.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories