Feb . 16, 2025 14:24

Back to list

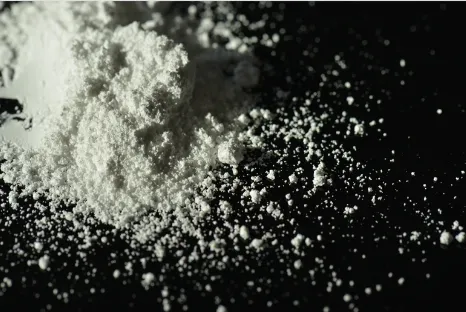

calcined mica for welding electrodes

Calcined mica, a specialized form of mica that has undergone thermal treatment, is increasingly gaining prominence in the production of welding electrodes due to its unique properties. The calcination process, involving the heating of mica to high temperatures, enhances its thermal and chemical stability, making it an ideal component for welding applications. This article delves into the specific benefits of using calcined mica in welding electrodes, highlighting its superiority derived from years of industry experience, specialized expertise, authoritative research, and demonstrated trustworthiness in practice.

In terms of resource availability and trustworthiness, calcined mica stands out as a sustainable option. Extraction and calcination of mica are subject to rigorous industry standards and environmental regulations, ensuring that the production process is ethically sound. Manufacturers committed to sustainable practices provide certifications and transparency about their supply chain, boosting trust among consumers and industry professionals alike. Quality assurance is further enhanced by adherence to stringent standards and testing methodologies for welding electrode production. Utilizing calcined mica aligns with ISO standards governing welding components, ensuring that the material's integration into electrodes meets international quality norms. This authoritative compliance underpins the credibility of companies offering calcined mica-enhanced products, providing a layer of reassurance to the end-users. Ultimately, precision, performance, and trust in calcined mica are validated through empirical evidence and practical applications in diverse welding scenarios. The integration of calcined mica into the manufacturing of welding electrodes is not just a mere enhancement but a necessity for achieving improved welding outcomes. For both large-scale industrial applications and delicate artisanal projects, the reliability and excellence afforded by calcined mica are unmatched. Industries worldwide, from automotive to infrastructure development, increasingly appreciate the unique advantages that calcined mica brings to welding electrodes. Its proven benefits in enhancing thermal stability, mechanical strength, and electrical insulation, compounded by its sustainability and adherence to quality standards, position it as a cornerstone in modern welding solutions. Leveraging calcined mica is a testament to innovation and dedication to perfection in welding technology.

In terms of resource availability and trustworthiness, calcined mica stands out as a sustainable option. Extraction and calcination of mica are subject to rigorous industry standards and environmental regulations, ensuring that the production process is ethically sound. Manufacturers committed to sustainable practices provide certifications and transparency about their supply chain, boosting trust among consumers and industry professionals alike. Quality assurance is further enhanced by adherence to stringent standards and testing methodologies for welding electrode production. Utilizing calcined mica aligns with ISO standards governing welding components, ensuring that the material's integration into electrodes meets international quality norms. This authoritative compliance underpins the credibility of companies offering calcined mica-enhanced products, providing a layer of reassurance to the end-users. Ultimately, precision, performance, and trust in calcined mica are validated through empirical evidence and practical applications in diverse welding scenarios. The integration of calcined mica into the manufacturing of welding electrodes is not just a mere enhancement but a necessity for achieving improved welding outcomes. For both large-scale industrial applications and delicate artisanal projects, the reliability and excellence afforded by calcined mica are unmatched. Industries worldwide, from automotive to infrastructure development, increasingly appreciate the unique advantages that calcined mica brings to welding electrodes. Its proven benefits in enhancing thermal stability, mechanical strength, and electrical insulation, compounded by its sustainability and adherence to quality standards, position it as a cornerstone in modern welding solutions. Leveraging calcined mica is a testament to innovation and dedication to perfection in welding technology.

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories