Jan . 14, 2025 12:01

Back to list

Calcined Mica F-60

Mica powder, a shimmering natural substance, has been increasingly hailed as an essential product across various industries. For centuries, artisans and enthusiasts alike have cherished its unique properties, recognizing it as more than just a decorative element. Here, we delve into the nuanced uses of mica powder, illuminating its transformative capabilities through firsthand experience and expert insights.

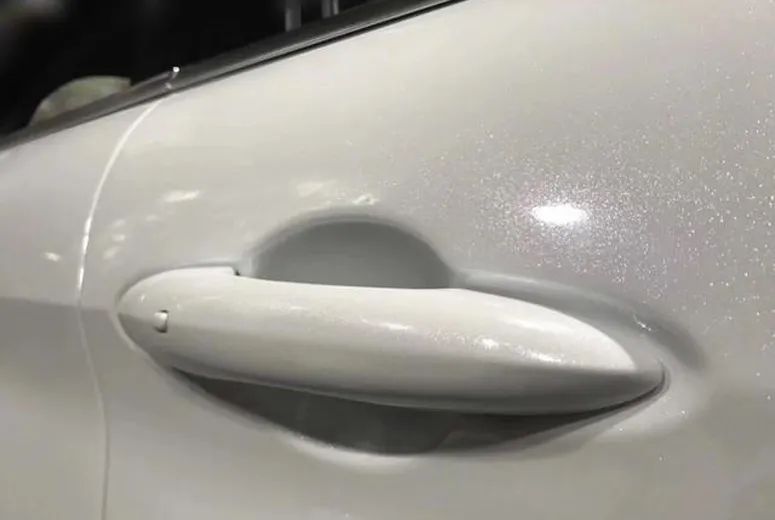

Moreover, in the burgeoning field of plastics, mica powder serves as a filler and reinforcement agent. Its incorporation into plastic not only enhances the mechanical properties but also improves thermal resistance, showcasing the material's multifaceted benefits. Experienced engineers and materials scientists tout its efficiency in boosting structural integrity while reducing production costs in mass manufacturing. Furthermore, mica powder’s inherent stability makes it a trusted component in the production of electronics. For decades, mica has been integral in insulating applications, prized for its heat-resistant properties. Its powdered form continues this legacy, being utilized in the development of thermal barriers and other insulating needs in advanced electronic devices. Industry experts continue to validate its indispensability in maintaining operational efficiency and safety standards in electronic manufacturing. In conclusion, mica powder's diverse applications across multiple industries exemplify its status as a versatile and essential material. Its widespread acceptance amongst professionals is not only a testament to its utility and effectiveness but also highlights its credibility as a trusted choice for enhancing both new and established products. Whether it's adding sparkle to cosmetics, crafting tools, enhancing vehicle finishes, reinforcing plastic products, or ensuring safety in electronics, mica powder is a genuine industry staple, synonymous with quality and reliability.

Moreover, in the burgeoning field of plastics, mica powder serves as a filler and reinforcement agent. Its incorporation into plastic not only enhances the mechanical properties but also improves thermal resistance, showcasing the material's multifaceted benefits. Experienced engineers and materials scientists tout its efficiency in boosting structural integrity while reducing production costs in mass manufacturing. Furthermore, mica powder’s inherent stability makes it a trusted component in the production of electronics. For decades, mica has been integral in insulating applications, prized for its heat-resistant properties. Its powdered form continues this legacy, being utilized in the development of thermal barriers and other insulating needs in advanced electronic devices. Industry experts continue to validate its indispensability in maintaining operational efficiency and safety standards in electronic manufacturing. In conclusion, mica powder's diverse applications across multiple industries exemplify its status as a versatile and essential material. Its widespread acceptance amongst professionals is not only a testament to its utility and effectiveness but also highlights its credibility as a trusted choice for enhancing both new and established products. Whether it's adding sparkle to cosmetics, crafting tools, enhancing vehicle finishes, reinforcing plastic products, or ensuring safety in electronics, mica powder is a genuine industry staple, synonymous with quality and reliability.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories