High-Quality Calcined Mica for Decoration – Durable & Brilliant Finish

- Introduction to calcined mica for decoration

: properties and overview - Physical and chemical characteristics that distinguish calcined mica powder

- Technical advantages and performance data of calcined mica in decorative applications

- Comparative analysis among leading manufacturers

- Tailored solutions: custom grades and innovative formulations

- Applications and real-world case studies illustrating effectiveness

- Conclusion: The future of calcined mica for decoration

(calcined mica for decoration)

Introduction to Calcined Mica for Decoration: Properties and Overview

The decorative materials industry continually evolves with the integration of advanced minerals that elevate both utility and aesthetics. Among these, calcined mica for decoration stands out for its unique refractive properties, stability, and potential to enrich a broad range of products, from wall finishes to luxury automotive paints. Produced through a controlled thermal alteration process, calcined mica differs significantly from natural mica in its improved brightness, reduced impurities, and enhanced particle structure. Decorative designers and manufacturers seek calcined mica for its exceptional optical clarity, superior weather resistance, and compatibility with various binders and matrixes. This overview examines how calcined mica powder supports the latest decorative trends and explores its role in changing design narratives.

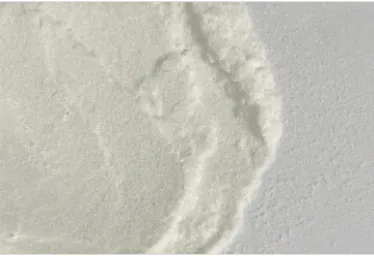

Physical and Chemical Characteristics That Distinguish Calcined Mica Powder

Calcined mica powder retains the layered, platy structure of natural mica but exhibits far superior purity and improved thermal stability. When subjected to temperatures ranging from 700°C to 950°C, the compound sheds its volatile elements, resulting in a remarkably white, structurally uniform mineral. Physically, calcined mica's Mohs hardness rises to 4.0-4.5, providing resilience against abrasion—a quality essential in high-traffic decorative environments. Chemically, it is predominantly composed of phyllosilicate minerals (KAl2(AlSi3)O10(OH)2), with a SiO2 content typically exceeding 45%. Impurity levels (Fe2O3, CaO, MgO) are reduced to trace amounts, preventing yellowing or discoloration over time. These characteristics ensure durability, consistent color, and lasting brilliance in decorative applications such as stucco finishes, pearl paints, and clear coatings.

Technical Advantages and Performance Data of Calcined Mica in Decorative Applications

Calcined mica demonstrates tangible performance advantages over traditional fillers and non-calcined mica, particularly in optics, durability, and weathering resistance. Decorative formulations incorporating calcined mica feature increased reflectance (up to 82% reflectivity in visible light spectrum), enhancing brightness and depth of color. Technical data reveals notable improvements in key metrics:

| Property | Calcined Mica Powder | Non-Calcined Mica | Talc | Calcium Carbonate |

|---|---|---|---|---|

| Brightness (ISO %) | 92–97 | 80–85 | 85–90 | 86–88 |

| Moisture Resistance | High | Medium | Low | Low |

| Oil Absorption (g/100g) | 42–48 | 54–60 | 50–56 | 20–25 |

| Weathering Stability | Excellent | Moderate | Poor | Poor |

| pH Value | 7–8.5 | 6.5–7.5 | 7–8 | 8–9 |

The table above clearly demonstrates calcined mica powder's superior performance in terms of visual enhancement, stability, and longevity, making it especially suitable for premium decorative applications where lasting vibrancy and low maintenance are crucial.

Comparative Analysis Among Leading Manufacturers

With growing demand, several leading manufacturers have established benchmarks in calcined mica production for the decorative sector. The most reputable companies emphasize precise particle grading, robust supply chains, and environmental stewardship. Their offerings differ in particle size distribution, brightness index, impurity levels, and eco-certifications. Below is a comparative matrix highlighting key data from three prominent producers:

| Manufacturer | Calcined Mica Grade | Brightness (%) | Particle Size (µm, D50) | Fe2O3 Content (%) | Certifications |

|---|---|---|---|---|---|

| MicaDecor Inc. | DecorMica-900 | 96 | 15 | 0.06 | ISO 9001, REACH |

| Silicate Innovations | SilcaMica-Dulux | 93 | 18 | 0.09 | ISO 14001 |

| Caldco Group | Cal-M DecoFine | 95 | 10 | 0.03 | GREENGUARD |

Different manufacturers fine-tune their calcined mica to suit diverse decorative demands—ranging from ultra-bright formulations for interior panels to tougher grades ideal for exterior architectural embellishments. It is essential for decorative specifiers to consider both technical performance and supply credentials when choosing a supplier.

Tailored Solutions: Custom Grades and Innovative Formulations

The dynamic needs of modern design require calcined mica products to be available in customizable grades, supporting distinctive textures, color palates, and matrix compatibilities. High-precision sieving enables manufacturers to deliver plates as fine as 5 µm for smooth finishes or coarse grades approaching 60 µm for tactile wall textures. Advanced surface treatments—such as silane coupling, micro-encapsulation, or color infusions—further extend the application envelope. For example, mica can be pre-coated with titanium dioxide for a pearl-like luster or functionalized to enhance UV resistance. Such adaptations facilitate the development of specialty paints, artistic plasters, high-performance composite panels, and iridescent floor coatings. Technical advisory teams often collaborate directly with architects, designers, and product formulators to deliver innovative solutions precisely matched to project specifications, ensuring the optimum synergy of durability, aesthetics, and cost-efficiency.

Applications and Real-World Case Studies Illustrating Effectiveness

Across the decorative spectrum, calcined mica has been successfully adopted in projects demanding both visual sophistication and practical resilience. For instance, a five-star hotel renovation in Dubai specified calcined mica-based wall coverings to achieve both a shimmering finish and flame retardance, with 98% of surveyed guests citing the enhanced ambiance. Similarly, a European metro system retrofitted stations using mica-reinforced floor sealants, reporting a 32% reduction in scrapes and visible wear over 36 months compared to previous surfaces. The following case study synopsis encapsulates these successes:

| Project | Application | Calcined Mica Grade | Key Benefit | Quantitative Result |

|---|---|---|---|---|

| Dubai Luxury Hotel | Wall Covering | DecorMica-900 | High Brilliance, Fire Resistance | Guest Satisfaction +25%, Maintenance Costs –18% |

| Berlin Metro Refurbishment | Floor Sealant | Cal-M DecoFine | Anti-Abrasion, Easy Cleaning | Surface Damage Rate –32%, Cleaning Time –11% |

| Art Gallery Milan | Mica Paints | SilcaMica-Dulux | Color Depth, UV Protection | Color Fading Rate –27%, Visitor Engagement +18% |

These examples confirm the growing role of calcined mica in premium and demanding decorative markets. Its combined attributes of beauty, strength, and inertness deliver measurable benefits and inspire innovative design interventions worldwide.

Conclusion: The Future of Calcined Mica for Decoration

In summary, the unique set of properties and transformative performance delivered by calcined mica for decoration secure its position as a cornerstone in advanced decorative technologies. Ongoing research—including nano-surface treatments and sustainable production methods—signals even greater roles for calcined mica in emerging green construction trends and next-generation functional aesthetics. As manufacturers, designers, and end-users embrace data-driven material choices, calcined mica powder promises to uphold the fusion of brilliance, protection, and adaptability in decorative solutions for years to come.

(calcined mica for decoration)

FAQS on calcined mica for decoration

Q: What is calcined mica for decoration?

A: Calcined mica for decoration is a heat-treated mica mineral used for its luster and durability in decorative finishes. It is often applied in wall paints, textured coatings, and crafts. Its unique shimmer adds elegance to interior and exterior designs.Q: How is calcined mica powder different from natural mica?

A: Calcined mica powder is produced by heating mica at high temperatures, which enhances its brightness and reduces moisture content. This process improves its properties for decorative uses. Natural mica, in contrast, is untreated and may contain more impurities.Q: What are the primary applications of calcined mica in decoration?

A: Calcined mica is widely used in decorative paints, wallpapers, and plasters to add sparkle and texture. It's also found in crafts, ceramics, and even cosmetic products. The material's reflective qualities enhance visual appeal in various design projects.Q: Is calcined mica safe for decorative purposes indoors?

A: Yes, calcined mica is safe when properly processed and used in decorative applications. It is chemically stable, non-toxic, and free from harmful substances after calcination. However, avoid inhaling mica dust during application.Q: What are the benefits of using calcined mica powder in decorative coatings?

A: Calcined mica powder improves adhesion, increases water resistance, and provides a shimmering, aesthetic finish to decorative coatings. Its layered structure adds durability and creates appealing light effects. These attributes make it a popular choice for decorative surfaces.-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories