Feb . 15, 2025 13:44

Back to list

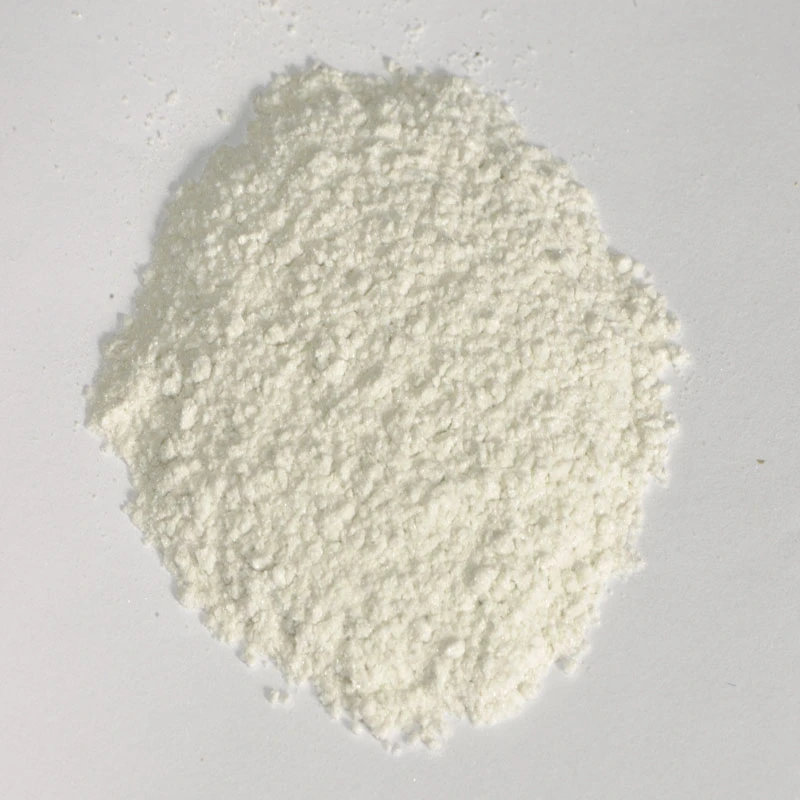

edible mica powder

Adding mica to candles can transform an ordinary candle-making venture into a mesmerizing craft experience, where each finished piece shimmers with unique charm and character. For candle makers seeking to elevate their creations, understanding the nuances of using mica is crucial, not only for achieving stunning visual effects but also for ensuring optimal burn performance.

Mica offers versatility beyond its fundamental role of adding shimmer. It can be combined with different wax types—soy, paraffin, beeswax—to achieve varied effects. Each wax type interacts uniquely with mica; for instance, soy might absorb and diffuse mica more evenly than paraffin, which can retain sharper, more concentrated bursts of color. The visual appeal of mica-enhanced candles does not solely rest in their shimmer. Candle artists can layer micas, creating gradients or ombre effects that amplify the decorative aspect. By thoughtfully selecting complementary or contrasting mica shades, candle makers can produce pieces that are not just functional but also exemplary of craftsmanship and design. Consumer safety and compliance play critical roles in the authoritative use of mica. Ensuring that mica is safe for candle burning involves verifying that supplements meet industry standards and are tested for reliability. Transparency in sourcing and adherence to safety guidelines reassure consumers, building trust in the product and brand. Clear labeling regarding mica use also educates buyers, promoting informed choices and establishing the brand's authority in the candle market. Lastly, the story behind each mica-infused candle brands the piece uniquely in the eyes of consumers. Sharing the inspiration, creation process, challenges, and triumphs not only engages customers but also embeds a narrative of expertise and authenticity. This kind of storytelling transforms a simple product description into a journey, inviting consumers to appreciate the skill and dedication behind the craft. Adding mica to candles is an artistic endeavor requiring knowledge, patience, and a dedication to quality. When executed with precision, it results in candles that stand as testaments to expertise and innovation, captivating consumers and setting standards in the craft of candle making.

Mica offers versatility beyond its fundamental role of adding shimmer. It can be combined with different wax types—soy, paraffin, beeswax—to achieve varied effects. Each wax type interacts uniquely with mica; for instance, soy might absorb and diffuse mica more evenly than paraffin, which can retain sharper, more concentrated bursts of color. The visual appeal of mica-enhanced candles does not solely rest in their shimmer. Candle artists can layer micas, creating gradients or ombre effects that amplify the decorative aspect. By thoughtfully selecting complementary or contrasting mica shades, candle makers can produce pieces that are not just functional but also exemplary of craftsmanship and design. Consumer safety and compliance play critical roles in the authoritative use of mica. Ensuring that mica is safe for candle burning involves verifying that supplements meet industry standards and are tested for reliability. Transparency in sourcing and adherence to safety guidelines reassure consumers, building trust in the product and brand. Clear labeling regarding mica use also educates buyers, promoting informed choices and establishing the brand's authority in the candle market. Lastly, the story behind each mica-infused candle brands the piece uniquely in the eyes of consumers. Sharing the inspiration, creation process, challenges, and triumphs not only engages customers but also embeds a narrative of expertise and authenticity. This kind of storytelling transforms a simple product description into a journey, inviting consumers to appreciate the skill and dedication behind the craft. Adding mica to candles is an artistic endeavor requiring knowledge, patience, and a dedication to quality. When executed with precision, it results in candles that stand as testaments to expertise and innovation, captivating consumers and setting standards in the craft of candle making.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories