Jan . 26, 2025 07:16

Back to list

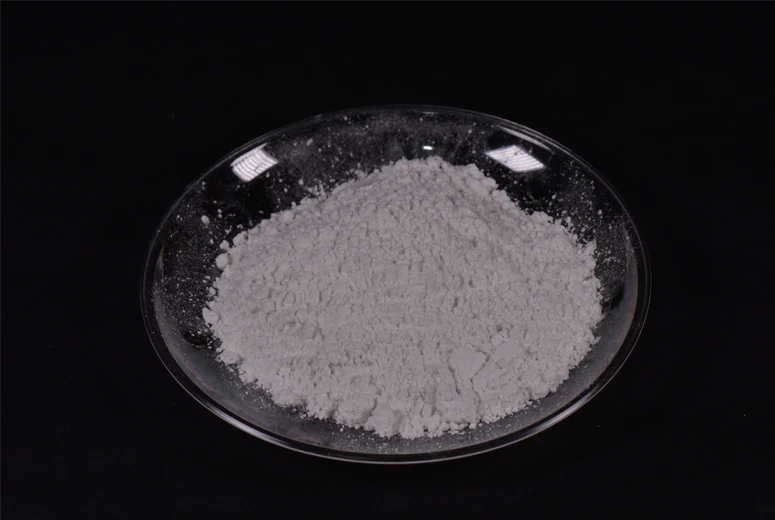

W-200 Muscovite Powder

Adding mica powder to resin can transform ordinary projects into shimmering works of art, offering both novices and seasoned artisans a unique way to explore their creativity. This combination is popular in various crafts, from jewelry making to creating stunning countertops. But achieving the best results involves understanding both the properties of mica powder and the nature of the resin you are working with.

Applying mica powder to resin involves several steps to ensure an even and thorough distribution. Begin by mixing the resin and hardener according to the manufacturer’s instructions. Once combined, gradually add the mica powder, stirring consistently to avoid clumps. It is advisable to add the powder slowly, checking the color and consistency before adding more. This gradual approach ensures that the resin maintains optimal flow and clarity. After mixing, promptly pour the resin mixture into the mold or onto the surface of your project. The resin’s working time is limited, and delays can result in uneven curing or undesired textures. Once the resin is laid, use a heat gun or torch to eliminate any bubbles that may have formed during mixing. This step not only enhances the visual finish but ensures a smooth surface without imperfections. Safety is a vital component of working with resin and mica powder. Always wear protective gear, including gloves and a mask, to prevent skin contact and inhalation of dust and fumes. Working in a well-ventilated space further mitigates exposure risks, ensuring a healthier crafting experience. Crafting with mica powder and resin is as much about the process as it is about the finished product. The creative possibilities are vast, whether producing custom coasters, intricate jewelry, or eye-catching decor pieces. By understanding the materials and techniques involved, artists can elevate their work, creating pieces that are not only beautiful but durable and respected in the industry. Through expert application and an appreciation for quality materials, adding mica powder to resin becomes an enriching endeavor in artistic expression.

Applying mica powder to resin involves several steps to ensure an even and thorough distribution. Begin by mixing the resin and hardener according to the manufacturer’s instructions. Once combined, gradually add the mica powder, stirring consistently to avoid clumps. It is advisable to add the powder slowly, checking the color and consistency before adding more. This gradual approach ensures that the resin maintains optimal flow and clarity. After mixing, promptly pour the resin mixture into the mold or onto the surface of your project. The resin’s working time is limited, and delays can result in uneven curing or undesired textures. Once the resin is laid, use a heat gun or torch to eliminate any bubbles that may have formed during mixing. This step not only enhances the visual finish but ensures a smooth surface without imperfections. Safety is a vital component of working with resin and mica powder. Always wear protective gear, including gloves and a mask, to prevent skin contact and inhalation of dust and fumes. Working in a well-ventilated space further mitigates exposure risks, ensuring a healthier crafting experience. Crafting with mica powder and resin is as much about the process as it is about the finished product. The creative possibilities are vast, whether producing custom coasters, intricate jewelry, or eye-catching decor pieces. By understanding the materials and techniques involved, artists can elevate their work, creating pieces that are not only beautiful but durable and respected in the industry. Through expert application and an appreciation for quality materials, adding mica powder to resin becomes an enriching endeavor in artistic expression.

Prev:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories