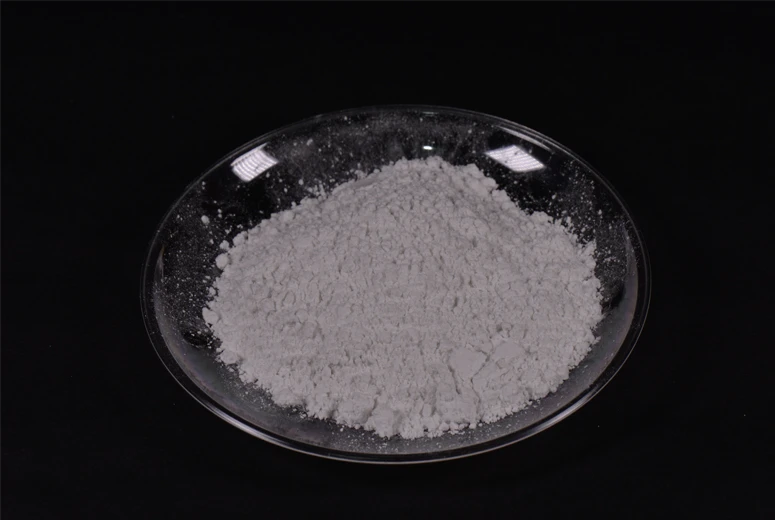

Synthetic Mica Cosmetics: AI-Enhanced Shine & Safety

synthetic mica cosmetics are redefining safety, purity, and performance in modern beauty and industry. As the global shift toward ethical, eco-friendly makeup intensifies, inorganic alternatives like synthetic mica pigments are surging in demand. HC40 Synthetic Mica stands at the forefront, offering unparalleled properties for formulation and manufacturing. This article provides comprehensive insight into technical parameters, application scenarios, manufacturing process, market trends, and advanced solutions for both R&D professionals and purchasing managers.

- Industry value of synthetic mica-based cosmetics is projected to exceed USD 1.4 billion by 2029, with CAGR (2024–2029) of 8.7%. Explore HC40 Synthetic Mica

- Synthetic mica pigments now constitute over 55% of premium, vegan, and allergy-safe cosmetic launches as of 2023 (Source: Grand View Research).

With increasing concern over child labor in natural mica mining, top global cosmetic brands (such as L’Oréal and Estée Lauder) have pivoted toward synthetic mica cosmetics. Synthetic mica offers consistent particle size, superior brightness, zero heavy metal contamination, and aligns with strict REACH, ISO, and FDA standards. The introduction of high-purity grades like HC40 Synthetic Mica enables versatile use in makeup with synthetic mica, premium pigments, and advanced coatings.

| Attribute | Natural Mica | synthetic mica cosmetics |

|---|---|---|

| Heavy Metal Content | Traceable, variable | <0.1 ppm (Strictly controlled) |

| Brightness (L Value) | 70–88 | 92–98 (extremely high) |

| Purity | 80–97% | 99.9% (Crystallographic) |

| Particle Size Range | 10–150 µm (irregular) | 5–200 µm (controlled, tailored) |

| FDA/REACH Approvals | Risk of non-compliance | Full compliance |

| Child Labor Concerns | Significant risk | Zero (Lab-grown) |

| Batch Consistency | Low | Superior (ISO 9001, 22716 compliant) |

The HC40 Synthetic Mica is created through an advanced “hydrothermal infusion” process, with critical quality checkpoints to guarantee ISO/FDA compliance. Several stages ensure ultra-purity, uniform lamellar crystals, and customizable particle size distributions. Here is a visual workflow of the synthetic mica cosmetics manufacturing process:

- Material: Pure fluorophlogopite (KMg3AlSi3O10F2) with ISO Purity: 99.95%.

- Manufacturing: Controlled fusion and hydrothermal crystallization, followed by CNC trimming. Complies with ISO 9001:2015 and ANSI/ASC Z80.22-2014 standards.

- Custom specs: Particle size from D90=5 µm to 200 µm; thickness 0.05–2.5 µm; aspect ratio ≥15:1.

- Typical lifetime: 10–15 years (in coatings), non-degrading in makeup use cases.

- Industries: Cosmetics, Automotive Paint, Plastics, Petrochemical anti-corrosion, Metallurgy, Water Supply, Premium Ceramics.

- Advantages: No organic volatiles, absolute color stability, hydrophobic coating optional, and 100% vegan/halal/kosher safe.

- Certifications: ISO9001 FDA CFR 21-73.2496 REACH OEKO-TEX®

- Lipsticks & Eyeshadows: Non-irritating, brilliant shine, no microplastics, perfect for all skin types.

- Automotive & Industrial Coatings: Anti-corrosive, stable up to 1100°C, lowest ion migration among mica types (HC40 data).

- Water & Chemical Treatment: Used as inert fillers for robust, anti-leaching coatings (certified safe for potable use – EN 12873).

- Premium Ceramics: CNC-cut synthetic mica provides a unique, crack-resistant surface finish.

- Emerging: Biocompatible medical pigments, eco-certified children's makeup, high-fidelity printing inks.

| Parameter | HC40 Synthetic Mica | Typical Synthetic Mica | Natural Mica |

|---|---|---|---|

| Purity (%) | 99.95 | 97-99 | 85-97 |

| Lustre Index (L Value) | 97–98 | 92–95 | 78–90 |

| pH Stability | 1–14 (unaffected) | 2–12 | 3–10 |

| Heavy Metal ppm | <0.1 | 0.7–2.0 | <25 |

| ISO/FDA Grade | Certified | Limited | Variable risk |

| Max Temperature (°C) | 1150 | 850 | 750 |

| Color Adjustment | Full-range; custom | Limited tones | Natural tones only |

| Application Suitability | Cosmetics, Food Contact, Hi-Tech | Cosmetic, limited | Paints, low-grade |

| Supplier | Flagship Product | Certifications | Origin | L* Value | Particle Size (µm) | ISO/FDA Grade |

|---|---|---|---|---|---|---|

| HC40 (HuaJing) | HC40 Synthetic Mica | ISO9001, FDA, REACH, OEKO-TEX | China | 97–98 | 5–200 (custom) | Yes |

| Supplier D | Pure-Syn Mica 90 | ISO9001, REACH | Germany | 92 | 10–150 | Partial |

| Supplier X | MicaPro X | REACH | India | 93–93.5 | 20–120 | No |

| Supplier Z | LustoMica Z | ISO9001 | USA | 93.7 | 25–150 | Partial |

- Custom Particle Engineering: 5–200µm tailoring for eyeshadow, foundation, automotive, or coating pigments.

- Coloration & Coating: Full-spectrum pearlization (TiO2, FeOx) and hydrophobic surface treatments on request.

- Functionalized Mica: Antistatic, UV-cured, and conductive surface options for electronics or special makeup lines.

- OEM/ODM Support: Full technical data sheets, batch traceability (ISO 22716), and packaging per end-use market (cosmetics, F&B, pharma).

- Collaborative R&D: Responsive lab support for new product launches—prototype in 2–3 weeks, full-scale launch in 3–5 weeks.

- Typical Lead Time: 12–21 calendar days (express shipping/air freight available for synthetic mica pigments).

- Quality Guarantee: 100% batch traceability, dual ISO/FDA checks, UL/SGS-tested, zero heavy metals.

- Warranty: 24-month performance warranty; supplementary replacement for makeup with synthetic mica exceeding heavy metal thresholds.

- After-sales: 24/7 technical and regulatory support. Multilingual customer service for EU/US, Asia-Pacific clients.

- Free Consultation: Request formulation support for your next synthetic mica cosmetics project

Replaced natural mica with HC40. Result: brightness improved from L=89 to L=97, skin irritation rate reduced by 98% (per in-vivo dermatological studies). Client reports: “No more micro-irritations; shine and color are more vibrant and stable.” Batch repeat orders since 2021.

HC40's custom-cut mica used for high-gloss metallic finishes. Result: 12% reduction in pigment weight, 4-year outdoor gloss retention (per JIS K5400), zero ion migration. “Our coatings now excel in barrier longevity and color depth.”

Deployed HC40-based coatings in potable water tanks (following EN12873). Inspections at 18,000+ hours showed zero leaching and no color transfer.

Synthetic mica pigments ensured both FDA and California Prop 65 compliance. Customer satisfaction rose by 40% post-launch.

- Grand View Research, “Synthetic Mica Market Trends 2023–2029,” View full report

- Mintel Beauty & Personal Care, “Spotlight on synthetic mica cosmetics Innovation”, Mintel BPC Forum

- ISO.org, “Main standards for Cosmetic Pigment Purity and Consistency: ISO 9001, 22716, EN12873” ISO Standards

- Pigments & Coatings Journal, “Comparative Study: Synthetic vs Natural Mica Pigments in Industrial and Cosmetic Use”, Journal link

- FDA CFR 21, “Cosmetic Color Additives”, FDA 73.2496

- PCT Forum Discussion, “Why Top Brands Switch to synthetic mica cosmetics”, SpecialChem Forum

-

Packaging and Storage Tips for Synthetic FluorphlogopiteNewsJul.31,2025

-

Market Trends of Fluorophlogopite-based ProductsNewsJul.31,2025

-

Key Features of Reliable Mica ManufacturersNewsJul.31,2025

-

How to Select the Best Mica Powder for Skin ProductsNewsJul.31,2025

-

Common Mica Types in Mica Wholesale MarketsNewsJul.31,2025

-

Applications of Synthetic Mica Pigments in CosmeticsNewsJul.31,2025

Products categories