Packaging and Storage Tips for Synthetic Fluorphlogopite

The growing popularity of fluorphlogopite synthetic in cosmetics and industrial applications makes proper packaging and storage essential for maintaining its exceptional properties. As a premium alternative in the synthetic mica vs natural mica debate, synthetic fluorphlogopite requires specific handling to preserve its unique characteristics like thermal stability and brilliant optical effects. Unlike natural mica variants, fluorphlogopite synthetic offers superior consistency but still demands careful attention to packaging solutions and storage conditions to prevent degradation or contamination. The debate of synthetic mica vs natural mica often highlights the advantages of synthetic fluorphlogopite, particularly its purity and customizable properties, but these benefits can only be maintained with appropriate storage protocols. Whether used in high-end cosmetics or advanced industrial applications, implementing proper packaging and storage methods for fluorphlogopite synthetic ensures optimal performance throughout its shelf life and usage period.

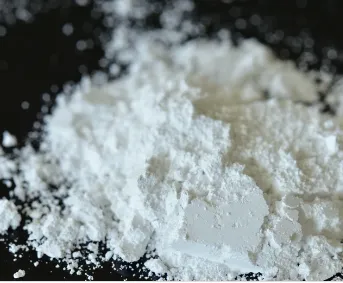

Optimal Packaging Solutions for Fluorphlogopite Synthetic

Selecting the right packaging for fluorphlogopite synthetic begins with understanding its sensitivity to moisture and physical damage. High-quality synthetic fluorphlogopite should be packaged in moisture-resistant containers with proper sealing mechanisms to prevent humidity absorption, which can affect its optical properties and flow characteristics. In the synthetic mica vs natural mica comparison, fluorphlogopite synthetic often comes with specialized surface treatments that require protection from environmental factors that natural mica might tolerate better. Multi-layer packaging incorporating aluminum foil barriers and desiccant packets helps maintain the integrity of synthetic fluorphlogopite during transportation and storage. For bulk quantities of fluorphlogopite synthetic, food-grade polyethylene liners within fiber drums provide both moisture protection and structural support. The packaging for synthetic fluorphlogopite should also consider end-use applications - cosmetic-grade materials often require smaller, resealable packages to maintain purity after opening, while industrial grades may utilize larger, heavy-duty containers. Proper labeling of fluorphlogopite synthetic packages with handling instructions, batch numbers, and expiration dates ensures traceability and proper usage throughout the supply chain.

Critical Storage Conditions for Synthetic Fluorphlogopite

Maintaining the quality of synthetic fluorphlogopite requires strict adherence to recommended storage conditions that differ somewhat from natural mica requirements. The ideal environment for storing fluorphlogopite synthetic maintains stable temperatures between 15-25°C (59-77°F) with relative humidity below 60%, as excessive moisture can compromise its surface treatments and optical performance. In the synthetic mica vs natural mica storage comparison, synthetic fluorphlogopite often demonstrates greater sensitivity to environmental fluctuations due to its engineered surface characteristics. Storage areas for fluorphlogopite synthetic should be clean, well-ventilated spaces away from direct sunlight and potential contaminants like dust or chemical fumes. Pallets of synthetic fluorphlogopite should be kept at least 10 cm (4 inches) off the floor and away from walls to ensure proper air circulation and prevent moisture absorption. First-in-first-out (FIFO) inventory management is particularly important for fluorphlogopite synthetic to ensure older stock gets used before its optimal performance period expires. Unlike some natural micas, synthetic fluorphlogopite typically has longer shelf stability when stored properly, but regular inspections of stored material are still recommended to detect any potential issues early.

Handling Considerations for Fluorphlogopite Synthetic

Proper handling procedures for fluorphlogopite synthetic help preserve its quality from warehouse to production line, differing in some aspects from natural mica protocols. When comparing synthetic mica vs natural mica handling requirements, synthetic fluorphlogopite often benefits from more consistent physical properties but may require gentler treatment due to specialized surface modifications. Personnel handling fluorphlogopite synthetic should use clean, dry tools and avoid unnecessary exposure to open air that could introduce moisture or contaminants. Transferring synthetic fluorphlogopite between containers should be done in low-humidity environments when possible, with care taken to prevent dust generation or electrostatic buildup. Unlike some natural micas, fluorphlogopite synthetic typically flows more uniformly but may require careful settling or gentle agitation to maintain homogeneity in storage containers. Safety measures for handling synthetic fluorphlogopite include using appropriate personal protective equipment like dust masks and goggles, particularly when working with fine powder forms. Proper handling of fluorphlogopite synthetic not only preserves material quality but also ensures worker safety and prevents cross-contamination in facilities processing multiple material types.

Synthetic Mica vs Natural Mica Storage Comparisons

The storage requirements for fluorphlogopite synthetic differ in several key aspects when examining synthetic mica vs natural mica preservation needs. While natural mica may tolerate broader environmental fluctuations due to its geological origins, synthetic fluorphlogopite often requires more controlled conditions to maintain its engineered properties. In the synthetic mica vs natural mica debate regarding shelf life, properly stored fluorphlogopite synthetic typically offers more consistent long-term performance without the variability sometimes seen in natural deposits. Packaging for synthetic fluorphlogopite frequently incorporates more advanced barrier technologies than traditional natural mica packaging, reflecting its higher value and performance specifications. The synthetic mica vs natural mica storage cost analysis often favors fluorphlogopite synthetic when considering reduced waste from consistent quality and longer usable life. However, synthetic fluorphlogopite may require slightly higher initial investment in storage infrastructure to maintain optimal conditions. These differences between synthetic mica vs natural mica storage protocols highlight why users transitioning to fluorphlogopite synthetic should review and potentially upgrade their storage facilities and procedures.

Synthetic Fluorphlogopite FAQs

What Are the Key Differences in Storing Fluorphlogopite Synthetic vs Natural Mica?

Fluorphlogopite synthetic generally requires stricter humidity control and protection from environmental contaminants compared to natural mica, though it offers more consistent quality over time when stored properly.

How Does Moisture Affect Synthetic Fluorphlogopite Performance?

Exposure to moisture can compromise surface treatments on fluorphlogopite synthetic, potentially altering its optical properties, flow characteristics, and dispersion capabilities in final applications.

In the Synthetic Mica vs Natural Mica Debate, Which Has Longer Shelf Life?

Properly stored synthetic fluorphlogopite typically maintains consistent quality longer than natural mica, which may vary more between batches due to natural mineral variations.

What Special Packaging Features Benefit Fluorphlogopite Synthetic?

High-barrier materials with moisture protection, UV-resistant outer layers, and proper sealing mechanisms help preserve synthetic fluorphlogopite quality during storage and transport.

Can Improper Storage of Synthetic Fluorphlogopite Be Corrected?

Some effects of improper storage on fluorphlogopite synthetic can be mitigated through controlled drying processes, but severe cases may require reprocessing or render the material unsuitable for premium applications.

For expert guidance on storing and handling premium fluorphlogopite synthetic, visit our website to access our comprehensive technical resources and product recommendations. Our specialists can help you optimize your synthetic fluorphlogopite storage solutions to maintain peak material performance and extend shelf life. Contact us today to discuss your specific requirements and discover how our high-quality fluorphlogopite synthetic products, backed by proper packaging and storage knowledge, can enhance your manufacturing processes and final product quality. Let us help you navigate the synthetic mica vs natural mica decision with confidence and implement best practices for your synthetic fluorphlogopite applications.

-

Market Trends of Fluorophlogopite-based ProductsNewsJul.31,2025

-

Key Features of Reliable Mica ManufacturersNewsJul.31,2025

-

How to Select the Best Mica Powder for Skin ProductsNewsJul.31,2025

-

Common Mica Types in Mica Wholesale MarketsNewsJul.31,2025

-

Applications of Synthetic Mica Pigments in CosmeticsNewsJul.31,2025

Products categories