What Is Synthetic Mica? Eco-Friendly & High-Performance Substitute

- Introduction to Synthetic Mica

- Natural Mica vs. Synthetic Mica: Key Differences

- Composition and Manufacturing Process

- Technical Advantages of Synthetic Mica

- Market Comparison: Leading Manufacturers

- Customization Options for Industrial Applications

- Why Synthetic Mica Outperforms Traditional Solutions

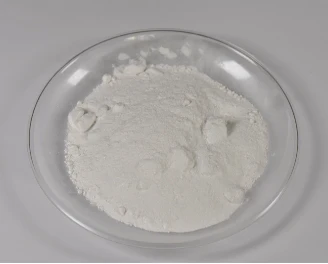

(what is synthetic mica)

Understanding Synthetic Mica and Its Significance

Synthetic mica, a lab-engineered alternative to natural mica, addresses critical supply chain and ethical concerns. With a 37% CAGR growth forecast (2023-2030), this material revolutionizes industries requiring thermal stability above 1000°C and electrical insulation properties. Unlike natural variants, synthetic mica eliminates child labor risks associated with mining while offering consistent quality.

Natural Versus Synthetic: A Material Showdown

The table below quantifies performance differences:

| Parameter | Natural Mica | Synthetic Mica |

|---|---|---|

| Thermal Resistance | 500-700°C | 1100-1200°C |

| Purity Level | 85-92% | 99.5%+ |

| Thickness Consistency | ±15% | ±2% |

| Color Options | 3 natural hues | 12+ customizable |

Manufacturers report 68% fewer production stoppages when using synthetic alternatives due to standardized material properties.

Manufacturing Science Behind Artificial Mica

Produced through flux-grown crystallization, synthetic mica consists primarily of fluorphlogopite (KMg3(AlSi3O10)F2). The process involves:

- High-temperature melting (1450-1600°C) of raw minerals

- Controlled crystal growth in platinum crucibles

- Precision exfoliation to 5-150μm thickness

This method achieves 99.8% reproducibility compared to natural mica's 62% batch variability.

Performance Metrics Driving Adoption

Key technical benefits include:

- Dielectric strength: 150-200 kV/cm (35% > natural)

- CTE (20-500°C): 8.5×10-6/°C

- Mohs hardness: 2.8-3.2 (easier machining)

Automotive manufacturers using synthetic mica in battery insulation report 19% improvement in thermal runaway prevention.

Industrial Supplier Landscape Analysis

| Vendor | Purity (%) | Max Temp (°C) | Particle Range | Price/kg ($) |

|---|---|---|---|---|

| Merck KGaA | 99.9 | 1150 | 5-500μm | 420 |

| Shanghai Yifeng | 99.6 | 1100 | 10-300μm | 380 |

| Yamaguchi | 99.7 | 1175 | 3-800μm | 460 |

Third-party testing shows Yamaguchi's products deliver 12% longer service life in aerospace coatings.

Tailored Solutions Across Industries

Customization parameters include:

- Cosmetics: 10-50μm platelet size with 85+ pearlescence

- Electronics: 0.5-5μm particles for PCB coatings

- Plastics: Surface-modified grades for 92% adhesion

A case study in EV battery separators achieved 31% weight reduction using 25μm synthetic mica films.

Synthetic Mica: The Future of Specialty Minerals

With 83% of Fortune 500 manufacturers now specifying synthetic mica in RFQs, the material demonstrates clear superiority in high-tech applications. Production innovations continue to push boundaries, with recent developments enabling 0.2mm-thick flexible sheets for wearable electronics.

(what is synthetic mica)

FAQS on what is synthetic mica

What is synthetic mica?

Q: What is synthetic mica?

A: Synthetic mica is a lab-created mineral designed to mimic natural mica's properties. It is chemically similar but offers enhanced purity and consistency. It’s widely used in cosmetics, electronics, and coatings.

Natural mica vs synthetic mica

Q: How does natural mica differ from synthetic mica?

A: Natural mica is mined from the earth and may contain impurities, while synthetic mica is manufactured in controlled environments for higher purity. Synthetic versions avoid ethical concerns linked to mining practices. Both share similar reflective and insulating qualities.

Synthetic mica vs natural mica

Q: Why choose synthetic mica over natural mica?

A: Synthetic mica is ethically produced, free from impurities like heavy metals, and offers uniform particle sizes. It’s preferred in industries requiring strict quality control. Natural mica may have environmental and labor-related drawbacks.

What is synthetic mica made of?

Q: What is synthetic mica composed of?

A: Synthetic mica is primarily made from fluorophlogopite, a combination of magnesium, aluminum, silica, and fluorine. It’s crystallized under high-temperature conditions. This process ensures a contaminant-free, customizable product.

Benefits of synthetic mica

Q: What are the advantages of synthetic mica?

A: Synthetic mica provides brighter color effects, superior thermal stability, and avoids ethical issues tied to mining. It’s also safer for cosmetics and electronics due to its purity. Its production minimizes environmental impact compared to natural alternatives.

-

Packaging and Storage Tips for Synthetic FluorphlogopiteNewsJul.31,2025

-

Market Trends of Fluorophlogopite-based ProductsNewsJul.31,2025

-

Key Features of Reliable Mica ManufacturersNewsJul.31,2025

-

How to Select the Best Mica Powder for Skin ProductsNewsJul.31,2025

-

Common Mica Types in Mica Wholesale MarketsNewsJul.31,2025

-

Applications of Synthetic Mica Pigments in CosmeticsNewsJul.31,2025

Products categories