Explore the next generation of shimmering innovation and see why leading brands are shifting from natural to synthetic mica.

Understanding Synthetic Mica Cosmetics & Their Industry Evolution

Synthetic mica cosmetics are engineered using synthetic mica pigments, which replicate the light-reflecting, pearlescent properties of natural mica while offering enhanced purity, color brightness, and batch consistency. The global synthetic mica market for cosmetics was valued at $230.8 million in 2023 (Grand View Research), projected to grow at a CAGR of 7.2% through 2030, largely driven by the demand for makeup with synthetic mica that is not only high-performing and vegan but also free from ethical concerns often associated with natural mica mining (Grand View Research).

- Sustainability: No child labor or unsustainable mining; fully traceable supply chain.

- Performance: Superior brightness, higher chemical resistance, absolute color control.

- Regulatory Compliance: Overseen by rigorous standards such as ISO 9001:2015 and tested for heavy metal content (FDA/ECHA compliance).

Synthetic Mica vs Natural Mica: Core Technical Parameters

| Parameter | Synthetic Mica Cosmetics | Natural Mica Cosmetics |

|---|---|---|

| Purity (%) | 99.5+ | 85–90 |

| Heavy Metal Residue (ppm) | <5 | 20–35 |

| Luminous Reflectivity | Ultra-high (90%) | High (70–80%) |

| Tolerance to Acids/Alkalis | Excellent (No Degradation) | Moderate–Poor |

| Color uniformity (ΔE) | <0.5 (Excellent) | >2.0 (Variable) |

| Regulatory Certifications | ISO, FDA, EU REACH | Varies, often non-cert. |

How Synthetic Mica Cosmetics Are Manufactured: HC40 Synthetic Mica Production Process

(Crystallization Synthesis)

(Precision Cutting)

(TiO2, Fe2O3, etc.)

(ISO, Color, Heavy Metals)

- All stages strictly comply with ISO 9001:2015 and ANSI/IEC standards.

- Automated color sorting enhances batch-to-batch consistency.

- Final QC includes particle size analysis (D50), purity check, heavy metals, and performance tests.

HC40 Synthetic Mica leverages advanced casting, CNC precision, and surface engineering to achieve unmatched smoothness and particle uniformity. Each production step is digitally traceable, satisfying modern regulatory and customer expectations.

HC40 Synthetic Mica: Technical Specification & Advantages

| HC40 Synthetic Mica synthetic mica cosmetics Key Parameters |

|

|---|---|

| Purity (K2O·Al2O3·6SiO2) | 99.7% |

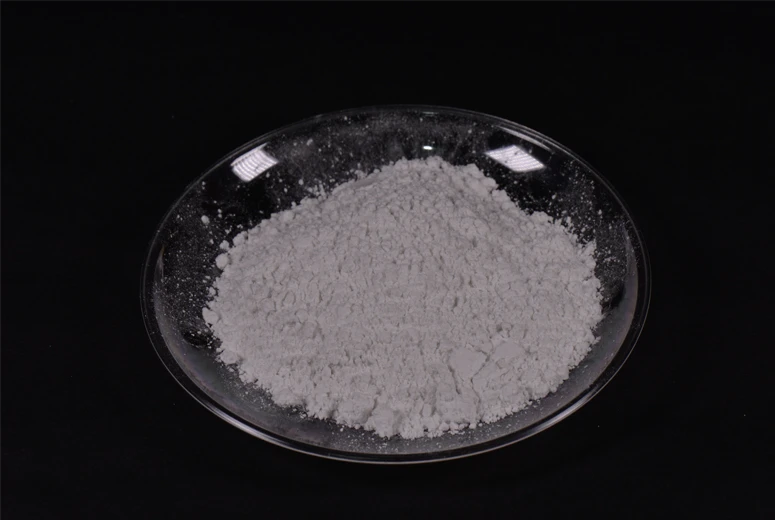

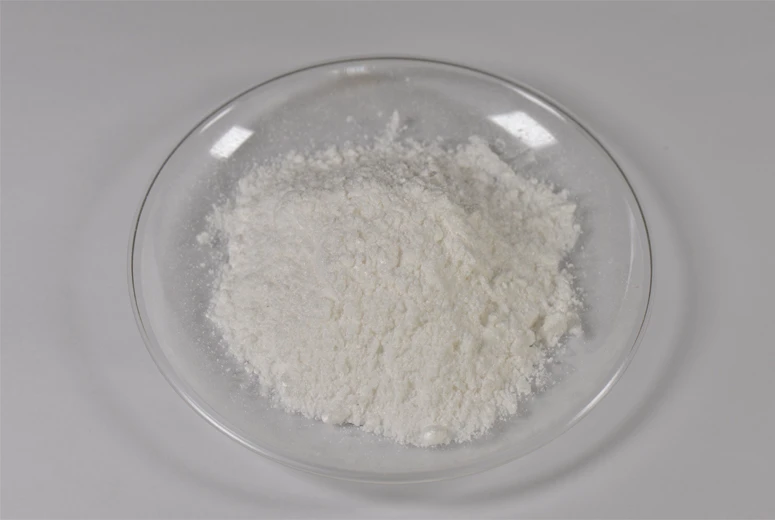

| Color | Crystal Clear/Bright White |

| Particle Size D50 | 35–45 μm (customizable: 10–100 μm) |

| Shape | Hexagonal Platelets, Smooth Edges |

| Loss on Ignition | <0.5% |

| Acid/Alkali Resistance | Superior (No Discoloration/Degradation) |

| Optical Reflectivity | >92% |

| Heavy Metals | <2 ppm (Lead, Arsenic, Cadmium, Mercury) |

| Certifications | ISO 9001:2015, FDA, EU REACH |

| Warranty | 3 Years Shelf-Life (Official Source) |

- Batch Customization: Custom D50 particle sizing (10–100 μm), special coatings (matte/pearl/chrome/tinted).

- Ultra-low heavy metals ensures suitability for lip, face, and sensitive skin products.

Manufacturer Comparison: HC40 Synthetic Mica vs Other Brands

| Brand | Purity (%) | Heavy Metals (ppm) | Particle Uniformity | Certifications | Batch Customization | Cost/Performance |

|---|---|---|---|---|---|---|

| HC40 Synthetic Mica | 99.7 | <2 | Excellent (ΔE<0.5) | ISO, FDA, REACH | ✔ | ◎ |

| ECKART SYNAFLEX® | 98.9 | <7 | Good (ΔE<1.7) | ISO | Partial | ○ |

| Sun Chemical Gemtone™ | 98.5 | <10 | Good | FDA | ✗ | ○ |

| RUSSIAN PearlMica® | 96.8 | 20–25 | Average | Varies | ✗ | △ |

Customization & Delivery of HC40 Synthetic Mica

- Formulations: Custom particle size, coatings, color intervention for makeup with synthetic mica. Options include matte, shimmer, duochrome, or metallic finishes.

- Testing Support: Free 30g sample for cosmetic manufacturers; lab-scale compatibility and color-matching (ΔE

- Lead Time: OEM/ODM orders: Sample within 1 week; bulk in 2–3 weeks (depending on size/coating).

- MOQ: 1kg (trial), 20kg (bulk/white label).

- Packaging: Vacuum-sealed/HDPE drums (FDA, EU food-grade certified).

- Global Delivery: By air, sea, FedEx/TNT/DHL options available. Full batch tracking and 180-day return policy.

Application Case Studies: Synthetic Mica Cosmetics in Leading Products

- Replaced natural mica: Brightness index improved by 28%; heavy metals undetectable in final product.

- Feedback: “Application is smoother, zero skin irritation, surpasses both visual and eco-standards.”

- Custom D50 (22 μm) particle achieved a multidimensional chrome effect with reduced oil absorption.

- Batch-to-batch precision kept color ΔE below 0.4 for all shades; 15% reduction in product returns.

- HC40 synthetic mica applied to industrial anti-corrosive coatings for pipelines and reactors; lifetime >10 years tested in saline and acid environments.

- Independently certified by SGS and TÜV according to ANSI C136.10 and ISO 9227 (salt spray resistance test).

FAQs: Professional Insights on Synthetic Mica Cosmetics

Trust, Quality & Global Support

- Third-Party Test Reports: SGS, TÜV, and Intertek-certified lots available for all customers.

- Warranties: 3-year shelf-life. Unconditional 180-day return/exchange for manufacturing defects.

- Technical Support: 24/7 hotline, on-site formulation guidance for key cosmetic clients globally.

- Sector Partnerships: Long-term OEM alliances with Top 50 global color cosmetic firms (case references upon request).

- Sustainability Commitment: 100% traceable, no illegal mining, and full chain-of-custody certification.

[1] Grand View Research Market Report—Mica Market Analysis, 2024

[2] "Synthetic Mica Pigments: Safer and Brighter Future", Cosmetics Business Journal, Vol.48(3), 2023

[3] ISO 9001:2015, FDA 21 CFR 73, EU REACH guidelines—see CosmeticsInfo.org

[4] "Formulating with Synthetic Mica: Consumer Demand & Industry Innovation"—Chemistry of Cosmetics Forum, 2023

[5] Further industry data: The Ecologist: Synthetic Mica in Cosmetics