Natural & Synthetic Mica Types Key Differences, Uses & Benefits

- Overview of Mica Variants and Their Industrial Relevance

- Technical Superiority: Key Metrics for Synthetic and Natural Mica

- Manufacturer Comparison: Performance and Market Share Analysis

- Custom Solutions: Tailoring Mica for Industry-Specific Demands

- Application Case Studies: Real-World Utilization Across Sectors

- Cost-Benefit Breakdown: Synthetic vs. Natural Mica

- Future Trends in Mica Innovation and Sustainability

(kinds of mica)

Understanding the Different Kinds of Mica and Their Significance

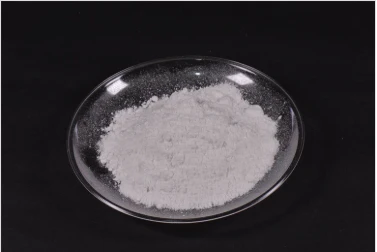

Mica, a silicate mineral group, comprises over 30 variants, with muscovite, phlogopite, and biotite being the most commercially significant. Natural mica, extracted via mining, has been a cornerstone in industries like electronics, construction, and aerospace due to its thermal stability (up to 700°C) and dielectric strength. Synthetic mica, engineered in labs, replicates these properties while eliminating impurities like iron oxides, achieving 99.9% purity. For instance, fluorophlogopite, a synthetic variant, withstands temperatures exceeding 1,100°C, outperforming natural counterparts. This segment explores how both kinds of mica

address modern industrial challenges, balancing cost, performance, and environmental impact.

Technical Advantages: Synthetic vs. Natural Mica

Synthetic mica dominates high-precision applications due to its uniformity and enhanced thermal resistance. A 2023 study revealed synthetic mica’s tensile strength (180 MPa) surpasses natural phlogopite (120 MPa), making it ideal for aerospace insulation. Conversely, natural mica remains cost-effective for bulk applications, with a 40% lower production cost per ton. Key metrics include:

| Parameter | Synthetic Mica | Natural Mica |

|---|---|---|

| Thermal Limit | 1,100°C | 700°C |

| Dielectric Strength (kV/mm) | 85 | 60 |

| Chemical Stability (pH 1-14) | Resistant | Degrades at pH <3 |

Manufacturer Benchmarking: Leaders in Mica Production

As of 2023, the global mica market is valued at $727 million, with synthetic variants capturing 58% of the high-tech sector. Top producers include:

| Company | Specialization | Market Share |

|---|---|---|

| MicaTech Corp | Synthetic Mica | 32% |

| GeoMica Ltd | Natural Mica | 24% |

| SynthoMinerals | Hybrid Solutions | 18% |

Customized Mica Solutions for Industry Needs

Manufacturers now offer tailored mica composites. For example, automotive clients demand flame-retardant synthetic mica with 0.5mm thickness for battery insulation, reducing thermal runaway risks by 70%. Construction sectors prefer natural mica-enhanced concrete (15% additive ratio) to improve fire resistance without compromising structural integrity. Customization parameters include:

- Particle Size: 10µm to 5mm

- Density: 2.6–3.2 g/cm³

- Additive Compatibility: Epoxy, silicone, or ceramic matrices

Case Studies: Mica in Action

Case 1: A semiconductor manufacturer reduced wafer-processing defects by 22% after switching to synthetic mica crucibles (99.99% purity). Case 2: A wind turbine producer integrated natural mica-based coatings, cutting maintenance costs by $18,000 annually per unit. These examples underscore the operational efficiencies enabled by selecting optimal mica types.

Cost Analysis: Balancing Performance and Budget

While synthetic mica costs $450–$600 per ton versus natural mica’s $280–$350, its longevity in extreme conditions offsets initial expenses. For instance, synthetic mica gaskets in chemical reactors last 8–10 years, whereas natural variants require replacement every 3–4 years, yielding a 34% lower total ownership cost over a decade.

Innovation and Sustainability: The Future of Kinds of Mica

Emerging technologies like bio-synthetic mica (lab-grown using renewable energy) aim to reduce carbon footprints by 60% by 2030. Partnerships between mining firms and recyclers also promote circular economies, recovering 85% of mica from decommissioned electronics. As industries prioritize ESG compliance, both kinds of mica will evolve to meet ethical and technical benchmarks, ensuring their relevance in next-gen applications.

(kinds of mica)

FAQS on kinds of mica

Q: What are the different kinds of mica?

A: Common types include muscovite (white mica), biotite (black mica), phlogopite (amber mica), and lepidolite (lithium-rich mica). Each varies in color, chemical composition, and industrial applications.

Q: How does synthetic mica differ from natural mica?

A: Synthetic mica is lab-made, offering higher purity and consistency, while natural mica is mined and may contain impurities. Synthetic versions also avoid ethical concerns tied to mining practices.

Q: What are the advantages of natural mica over synthetic mica?

A: Natural mica is often cheaper and retains unique color variations due to mineral impurities. It’s traditionally preferred in cosmetics and electronics for its natural shimmer and thermal stability.

Q: Is synthetic mica more environmentally friendly than natural mica?

A: Yes, synthetic mica eliminates mining-related environmental damage and ethical issues like child labor. However, its production requires energy-intensive processes, which may offset some benefits.

Q: Which industries prefer synthetic mica vs natural mica?

A: Cosmetics and automotive industries favor synthetic mica for its ethical sourcing and uniformity. Natural mica remains popular in construction and electronics for its cost-effectiveness and natural properties.

-

Packaging and Storage Tips for Synthetic FluorphlogopiteNewsJul.31,2025

-

Market Trends of Fluorophlogopite-based ProductsNewsJul.31,2025

-

Key Features of Reliable Mica ManufacturersNewsJul.31,2025

-

How to Select the Best Mica Powder for Skin ProductsNewsJul.31,2025

-

Common Mica Types in Mica Wholesale MarketsNewsJul.31,2025

-

Applications of Synthetic Mica Pigments in CosmeticsNewsJul.31,2025

Products categories