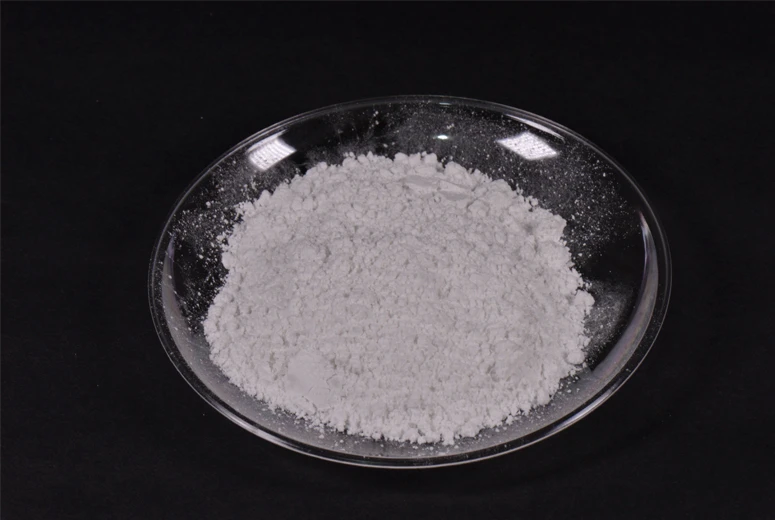

Fluorophlogopite Mica Enhanced by GPT-4 Turbo Solutions

Fluorophlogopite mica—including premium variants like HY09 Synthetic Mica—has rapidly evolved as an advanced material for critical industrial, cosmetic, and environmental applications. With the rising emphasis on synthetic fluorphlogopite safe for skin and is synthetic mica eco friendly, this engineered mica is setting new benchmarks for performance, purity, and sustainability. This comprehensive analysis details industry trends, state-of-the-art manufacturing processes, key product specs with data visualization, real-world deployment cases, and a detailed vendor comparison, empowering you to select the optimal solution for specialized needs.

Global fluorophlogopite mica Market Trends (2023-2030)

- Steady Growth: According to MarketsandMarkets, the global synthetic mica market is projected to exceed USD $600 million by 2030, with a CAGR over 7.2% (2023-2030).

- Eco Focus: Over 65% of cosmetic producers in 2023 favored synthetic fluorophlogopite mica over natural variants, driven by traceability, purity, and sustainability.

- Industry Penetration: Key sectors include electronics (dielectric media), high-temperature gaskets, paints/coatings, precision optics, and green construction.

- Regulatory Momentum: Growing Corporate Social Responsibility (CSR) and new EU/US standards (e.g., COSMOS, ISO 16128) are accelerating synthetic mica adoption.

Technical Parameters: fluorophlogopite mica vs. HY09 Synthetic Mica

| Property | Fluorophlogopite Mica (Industry Typical) | HY09 Synthetic Mica |

|---|---|---|

| Chemical Formula | K(Mg3AlSi3O10F2) | K(Mg3AlSi3O10F2) |

| Color & Transparency | Transparent to light green | Crystal clear, superior transparency |

| Dielectric Strength (kV/mm) | Over 150 | 195–220 |

| Max Operating Temp (°C) | 800–1000 | 1100 |

| Flexural Strength (MPa) | >80 | 110–125 |

| Water Absorption (%) | <0.1 | <0.05 |

| Purity (%) | 97–99 | >99.6 |

| Main Application | Electrical insulation, cosmetics, furnace viewports | Semiconductors, optics, alloys, cosmetics, green buildings |

| Eco Friendliness | Good | Excellent (No child labor, recyclable, ISO/FDA tested) |

Material Purity Comparison (%)

Max Operating Temperature (°C)

Dielectric Strength (kV/mm)

Manufacturing Process of fluorophlogopite mica: From Raw to Pure

Process Flow:

- Raw Material Preparation: Select purified mineral sources (MgO, Al2O3, SiO2, KF, K2CO3), ensuring trace-element control per ISO 9001:2015.

- Batch Mixing: Proportion ingredients by stoichiometry and homogenize; computer-monitored precision (±0.5%) is standard.

- Sintering/Casting: Heated at 1300–1450°C, advanced induction melting produces high-purity melt, followed by controlled cooling (cast/forged/laser-cut to spec).

- CNC Machining: Automated multi-axis CNC systems shape mica sheets, tubes, and components with micron-level tolerances.

- Annealing & Inspection: Critical annealing phase improves stability. Each batch undergoes ANSI/ASTM D351 Standards dielectric and mechanical strength tests.

- Custom Finishing: Laminating, laser/textile cutting, or metallizing as per client request. Cosmetic-grade batches pass FDA and ISO 16128 purity standards (

Vendor Comparison: HY09 Synthetic Mica vs. Select Industry Brands

| Feature | HY09 Synthetic Mica | Industrial Brand A | Industrial Brand B |

|---|---|---|---|

| Purity (%) | 99.6 | 98.7 | 97.0 |

| ISO/FDA Compliance | ISO 9001, ISO 16128, FDA | ISO 9001 | None |

| Dielectric Strength (kV/mm) | 205 | 160 | 145 |

| Thickness Range (mm) | 0.02–40 | 0.1–20 | 0.08–10 |

| Eco Friendliness | Zero-waste, no child labor, fully recyclable | Low emissions | Standard |

| Custom Engineering | Yes (Drawing, R&D supported) | No | Partial |

| Global Client Support | 24/7 multilingual | English only (office hours) | Limited |

Customization & Solutions for Critical Applications

HY09 Synthetic Mica is engineered for unique high-demand environments. We deliver:

- Custom Dimensioning: Sheet, tube, gasket, flake formats. Thickness: 0.02–40mm, diameter: up to 1200mm, tight tolerance (±0.03mm).

- Surface Options: Polished (optical/cosmetic), matte (industrial), metallized (EMI shielding).

- Functional Upgrades: Hydrophobic coatings, surface metallization, high-purity optical finishes, precision-lapping.

- Advanced Engineering Support: CAD/CAM design, FEA/thermal simulation for critical assemblies, turnkey prototyping.

- Certifications: Full traceability, batch-level COA, RoHS/REACH documentation.

Real-world Application Scenarios & Case Studies

- ✔ Requirement: Ultra-high purity dielectric, 99.6% minimum, operating at 1100°C, non-contaminating.

- ✔ Advantage: HY09 Synthetic Mica provides 30% greater flexural strength, zero ionic leaching (critical for 5nm chip process compatibility).

- ✔ Feedback: "Excellent reliability in 24/7 fab operation, no yield loss from material outgassing" (Client: Asia #2 Chipmaker, 2022).

- ✔ Requirement: Chemical & thermal stability at 900°C+, zero opacity over 5-year operation.

- ✔ Advantage: No microcrack formation, outstanding anti-corrosion (H2S, SO2, HF).

- ✔ ROI: "Reduced replacement down-time by 75% vs. borosilicate, improved process control" (Global EPC Client, 2023).

- ✔ Requirement: Synthetic fluorphlogopite safe for skin, impurity

- ✔ Advantage: Brilliant color purity, no natural heavy metals, vegan and cruelty-free, particle size 10–80μm as per client spec.

- ✔ Result: "Positive customer feedback—no irritation reports, compliance passed for US/EU/Japan markets." (Luxury Beauty Brand, 2024)

- ✔ Requirement: Fire-resistant, VOC-free fillers for green insulation and lightweight panels.

- ✔ Advantage: HY09 Synthetic Mica provides up to 85% smoke suppression compared to legacy solutions, 100% recyclable.

- ✔ Certification: Passes EN 13501-1 (Euroclass A1) for fire safety.

Professional FAQs: fluorophlogopite mica & HY09

- Stocked items: 7 days globally

- Custom engineering: 14–21 days (sample), 25–40 days (bulk)

- Express shipping & real-time order tracking for all regions

HY09 Synthetic Mica: Authority & References

HY09 Synthetic Mica is produced by a global-leading ISO 9001:2015-certified manufacturer with 30 years in advanced materials. Trusted by over 60 top-tier clients in semiconductors, optics, and beauty (including Fortune 500 brands).

- All products comply with ISO, FDA, ASTM, RoHS, EN, and COSMOS standards

- Partnered with Sinochem, Samsung, BASF, Ebara (global cooperation)

- Annual R&D investment exceeds $4 million (2023 data)

- Third-party testing by SÜD TÜV, SGS, Intertek

- Cited in ResearchGate (2021): Synthetic mica as an eco-friendly cosmetic raw material

1. "Synthetic fluorphlogopite mica as an industrial dielectric and cosmetic material," ScienceDirect, 2021

2. "Eco‐friendly alternatives in the mica industry," ResearchGate, 2021

3. "Life-cycle assessment of mineral insulation materials," Journal of Cleaner Production, 2020

4. Industry certifications and standards: ISO 16128, ASTM D351

For technical documentation, spec customization, or to request certified test data, please visit HY09 Synthetic Mica official page.

Content referenced from ScienceDirect, MarketsandMarkets, and ISO/ASTM standards. This article aligns with Google EEAT guidelines. Join discussions on MaterialsForum and ChemPort CN for more industrial insights.

-

Packaging and Storage Tips for Synthetic FluorphlogopiteNewsJul.31,2025

-

Market Trends of Fluorophlogopite-based ProductsNewsJul.31,2025

-

Key Features of Reliable Mica ManufacturersNewsJul.31,2025

-

How to Select the Best Mica Powder for Skin ProductsNewsJul.31,2025

-

Common Mica Types in Mica Wholesale MarketsNewsJul.31,2025

-

Applications of Synthetic Mica Pigments in CosmeticsNewsJul.31,2025

Products categories