Feb . 17, 2025 15:47

Back to list

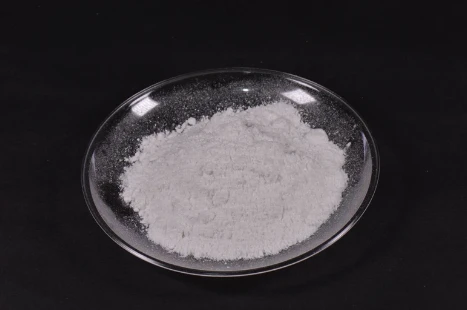

mica processing plant

In the dynamic realm of industrial mineral processing, the mica processing plant stands as a critical component that transforms raw mica into high-quality materials that fuel various industries. Known for its unique properties like thermal resistance, electrical insulation, and chemical inertness, mica is a mineral in high demand across sectors such as electronics, automotive, and cosmetics. To understand the intricacies behind a successful mica processing plant, one must delve into the experience, expertise, authoritativeness, and trustworthiness that define this facility.

Authoritativeness is evidenced in a mica processing plant's commitment to sustainability and environmental stewardship. Compliance with stringent environmental regulations not only enhances the plant’s credibility but also aligns with global efforts towards sustainable mining practices. Initiatives such as responsible sourcing, water recycling systems, and waste management protocols are indispensable components that assert the plant's position as a leader in the industry. These measures demonstrate the plant's dedication to minimizing ecological impact while balancing economic viability, reinforcing its authoritative voice in the discourse on sustainable mining. At the core of a thriving mica processing operation is trustworthiness, built through transparent communication and consistent delivery of high-quality products. Establishing long-term partnerships with suppliers and clients hinges upon this trust. By maintaining open lines of dialogue, a mica processing plant ensures mutual understanding and alignment on quality expectations, shipment schedules, and compliance standards. Furthermore, third-party audits and certifications act as testimonials to the plant's commitment to integrity and excellence. In conclusion, a mica processing plant is far more than an industrial facility; it is an ecosystem thriving on continuous improvement and innovation. Its success is measured by the experience and expertise of its workforce, the authoritative practices it upholds, and the trust it builds with stakeholders. As industries increasingly rely on specialized mineral products, the role of such plants becomes ever more pivotal, embodying a blend of technical prowess and ecological mindfulness. In doing so, they not only propel economic growth but also contribute responsibly to the global supply chain, setting benchmarks for future-oriented mineral processing practices.

Authoritativeness is evidenced in a mica processing plant's commitment to sustainability and environmental stewardship. Compliance with stringent environmental regulations not only enhances the plant’s credibility but also aligns with global efforts towards sustainable mining practices. Initiatives such as responsible sourcing, water recycling systems, and waste management protocols are indispensable components that assert the plant's position as a leader in the industry. These measures demonstrate the plant's dedication to minimizing ecological impact while balancing economic viability, reinforcing its authoritative voice in the discourse on sustainable mining. At the core of a thriving mica processing operation is trustworthiness, built through transparent communication and consistent delivery of high-quality products. Establishing long-term partnerships with suppliers and clients hinges upon this trust. By maintaining open lines of dialogue, a mica processing plant ensures mutual understanding and alignment on quality expectations, shipment schedules, and compliance standards. Furthermore, third-party audits and certifications act as testimonials to the plant's commitment to integrity and excellence. In conclusion, a mica processing plant is far more than an industrial facility; it is an ecosystem thriving on continuous improvement and innovation. Its success is measured by the experience and expertise of its workforce, the authoritative practices it upholds, and the trust it builds with stakeholders. As industries increasingly rely on specialized mineral products, the role of such plants becomes ever more pivotal, embodying a blend of technical prowess and ecological mindfulness. In doing so, they not only propel economic growth but also contribute responsibly to the global supply chain, setting benchmarks for future-oriented mineral processing practices.

Prev:

Latest news

-

Paint with Mica and Heat Reflective PropertiesNewsApr.16,2025

-

Enhancing Interior Walls with Thermal Paint and Mica PigmentNewsApr.16,2025

-

Mica Powder Paint: The Perfect Solution for Waterproofing and DurabilityNewsApr.16,2025

-

Mica Powder for Paint: A Unique Aesthetic and Protective SolutionNewsApr.16,2025

-

Mica Paint Powder: Enhancing Automotive and Industrial CoatingsNewsApr.16,2025

-

Allure of Mica Pigment Paint: Unlocking Shimmer and Color RangeNewsApr.16,2025

Products categories