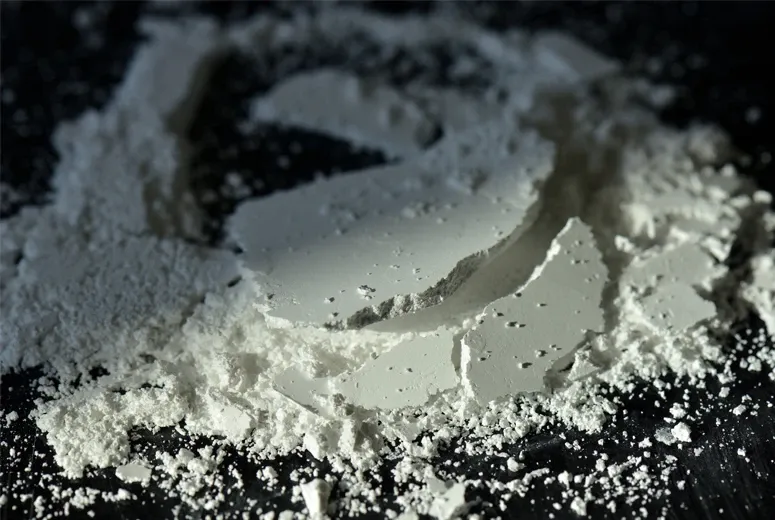

automotive pearl pigment powder

Automotive pearl pigment powder has revolutionized the car painting industry, offering a lustrous an...

ingredients in mica powder_pearl powder for automotive paint

Automotive pearl pigment powder has revolutionized the car painting industry, offering a lustrous an...

ingredients in mica powder_pearl powder for automotive paint

The future of mica mineral powder looks promising as its applications continue to expand across multiple industries. From construction and manufacturing to cosmetics and electronics, mica mineral powder remains a critical component due to its versatile properties and wide range of benefits. As innovation in these industries progresses, mica mineral powder is likely to play an increasingly important role in meeting the demands for performance, sustainability, and aesthetics.

3. Improved UV Resistance In addition to thermal stability, mica powder can also enhance UV resistance. Soft plastics are often subjected to sunlight and other environmental factors that can cause degradation over time. By adding mica powder, manufacturers can improve the material’s ability to withstand UV rays, ensuring longer-lasting color and structural integrity.

Mica is a mineral that has gained significant attention due to its unique properties and wide array of applications. Composed of silicate minerals, its notable characteristics include excellent electrical insulation, thermal stability, and resistance to moisture and chemicals. These properties make mica an invaluable raw material across various industries, including cosmetics, electronics, paints, and construction.

Mica is a versatile and crucial mineral celebrated for its unique physical and chemical properties. Used extensively in industries ranging from cosmetics and electronics to paint and construction, mica's significance cannot be overstated. However, the process of extracting and refining mica involves complex procedures, typically conducted in specialized mica processing plants. This article explores the role of mica processing plants and highlights their importance in ensuring the responsible and efficient production of this valuable mineral.

Natural mica powder and synthetic mica powder also have great differences in electrical insulation, mechanical properties, chemical stability, application range and cost. Natural mica powder has good electrical insulation, but the volume resistivity is lower than that of synthetic mica. Synthetic mica powder has better electrical insulation properties, high volume resistivity and stable dielectric constant, and is suitable for high performance electrical insulation materials. The hardness of natural mica powder is relatively low (2-3), and it has good elasticity and peeling property. The hardness of synthetic mica powder is higher (between 3 and 4), and the tensile strength and compressive strength are better than that of natural mica powder. Natural mica powder is stable in acid-base solution, but it is easy to decompose at high temperature. Synthetic mica powder is stable to acid and base at room temperature, but will be slowly corroded by sulfuric acid above 300℃. Better thermal stability, not easy to release gas. Natural mica powder is widely used in electrical appliances, welding rods, rubber, plastics, paper making, paint and other fields. Synthetic mica powder is mainly used in high-end electrical insulation materials, aviation, aerospace, national defense industry and other high-tech fields. Because synthetic mica powder needs to be produced through complex chemical processes, its production cost is usually higher than that of natural mica powder. Therefore, in the market, the price of synthetic mica powder is often higher than that of natural mica powder. However, with the continuous progress of production technology and the gradual emergence of scale effects, the price of synthetic mica powder is expected to gradually decrease.

The Benefits and Uses of Organic Mica Powder

Uses of Organic Mica Powder

In addition, lepidolite and ferrolepidolite can also be used as mineral raw materials for extracting lithium.

X { Y2-3 [Z4O10] (OH)2 }

X { Y2-3 [Z4O10] (OH)2 }

Mica has a wide range of uses, in ancient China, it is often used to do traditional Chinese medicine, the ancients even think that taking mica: a year to remove all diseases (heavy metal poisoning), three years of long service, husband into a boy (body scrap), Zhongshan uncle Qing suit, over time can become a cloud (soul ascension). However, in the era without glass, the transparency of mica makes it a better decorative material, for example, we are familiar with the mica screen candle shadow deep, the river gradually falling Xiaoxing sink. Mica screen is low, tassel tent is small and mica calf car.

The Impact of Mica in the Beauty Industry A Closer Look at Mica Video

- Start Small If you're new to mixing mica powder with paint, start with a small batch. This allows you to experiment without wasting materials.

- Blush and Contour Pigment powders can also be used to create natural-looking blushes and contour products, allowing users to sculpt and define their features.

Natural mica powder and synthetic mica powder also have great differences in electrical insulation, mechanical properties, chemical stability, application range and cost. Natural mica powder has good electrical insulation, but the volume resistivity is lower than that of synthetic mica. Synthetic mica powder has better electrical insulation properties, high volume resistivity and stable dielectric constant, and is suitable for high performance electrical insulation materials. The hardness of natural mica powder is relatively low (2-3), and it has good elasticity and peeling property. The hardness of synthetic mica powder is higher (between 3 and 4), and the tensile strength and compressive strength are better than that of natural mica powder. Natural mica powder is stable in acid-base solution, but it is easy to decompose at high temperature. Synthetic mica powder is stable to acid and base at room temperature, but will be slowly corroded by sulfuric acid above 300℃. Better thermal stability, not easy to release gas. Natural mica powder is widely used in electrical appliances, welding rods, rubber, plastics, paper making, paint and other fields. Synthetic mica powder is mainly used in high-end electrical insulation materials, aviation, aerospace, national defense industry and other high-tech fields. Because synthetic mica powder needs to be produced through complex chemical processes, its production cost is usually higher than that of natural mica powder. Therefore, in the market, the price of synthetic mica powder is often higher than that of natural mica powder. However, with the continuous progress of production technology and the gradual emergence of scale effects, the price of synthetic mica powder is expected to gradually decrease.

Over the past few years, the price of golden mica has shown notable fluctuations. In a stable market, prices can range significantly based on quality, purity, and sourcing credentials. Ethical sourcing, which adheres to labor regulations and fair trade principles, usually commands a premium price. Consequently, brands that prioritize sustainability and transparency can pass on these costs to the consumer.

An authoritative voice in the mica manufacturing sector conveys reliability. Leading manufacturers often participate in research initiatives and industry forums, sharing insights that drive the sector forward. This not only includes developments in product quality but also encompasses sustainable mining and processing practices. The drive towards eco-friendly operations is gaining momentum, with top manufacturers reducing environmental footprints through responsible sourcing and waste-reduction techniques. Their commitment to sustainability speaks to a greater trustworthiness, aligning with global consumer priorities.

Mica powder is a naturally occurring mineral dust, often used in cosmetics, arts and crafts, and even food products. Its shimmering effect and wide range of colors have made it a popular choice in various applications, including makeup, resin art, and soap making. Mica powder is made from ground mica, a group of silicate minerals that yields a shiny, reflective powder. However, its application in tie-dyeing presents some challenges and considerations.

Why Choose Mica Powder for Coloring Epoxy Resin?

Take pearlescent pigments as an example, pearlescent pigments are a class of pigments with pearl luster, which are deposited on the substrate (generally natural mica, synthetic mica, glass sheet and other sheet-like materials) above a layer or alternately deposited multiple layers of metal oxides or non-metallic oxides and formed a flat sandwich body with a structure similar to sandwich. Due to the difference in refractive index between the substrate and the oxide deposited on its surface and each oxide, when the light shines on the surface of the pearlescent pigment, the incident light will be refracted and reflected at the interface of each layer of the pearlescent pigment, and the color of the pearlescent pigment that people see is the result of the superposition of light after multiple refractions and reflections of the light, that is, the interference phenomenon of light.

The Significance of Mica Raw A Deep Dive into Its Uses and Applications

Layer upon layer of mica

Төлөвлөсөн зардал

Conclusion

Moreover, the use of pearl powder is not just about beauty; it also serves practical purposes. Car paints infused with pearl powder often exhibit improved durability and resistance to environmental factors. This natural ingredient can enhance the paint’s ability to withstand UV rays, preventing fading and discoloration over time. Additionally, pearl powder can contribute to better scratch resistance, making it a smart choice for those wanting to maintain the pristine look of their vehicles in the face of everyday wear and tear.