Natural mica powder and synthetic mica powder also have great differences in electrical insulation, mechanical properties, chemical stability, application range and cost. Natural mica powder has good electrical insulation, but the volume resistivity is lower than that of synthetic mica. Synthetic mica powder has better electrical insulation properties, high volume resistivity and stable dielectric constant, and is suitable for high performance electrical insulation materials. The hardness of natural mica powder is relatively low (2-3), and it has good elasticity and peeling property. The hardness of synthetic mica powder is higher (between 3 and 4), and the tensile strength and compressive strength are better than that of natural mica powder. Natural mica powder is stable in acid-base solution, but it is easy to decompose at high temperature. Synthetic mica powder is stable to acid and base at room temperature, but will be slowly corroded by sulfuric acid above 300℃. Better thermal stability, not easy to release gas. Natural mica powder is widely used in electrical appliances, welding rods, rubber, plastics, paper making, paint and other fields. Synthetic mica powder is mainly used in high-end electrical insulation materials, aviation, aerospace, national defense industry and other high-tech fields. Because synthetic mica powder needs to be produced through complex chemical processes, its production cost is usually higher than that of natural mica powder. Therefore, in the market, the price of synthetic mica powder is often higher than that of natural mica powder. However, with the continuous progress of production technology and the gradual emergence of scale effects, the price of synthetic mica powder is expected to gradually decrease.

- Basements and Foundations Preventing water seepage in areas that are prone to flooding or dampness is crucial. Waterproof paint can protect basement walls and floors, ensuring a dry and comfortable environment.

waterproof paint

Tips for Using Mica Powder Paint

The majority of mica originates from countries like India, Madagascar, and China. India is particularly prominent in the mica market, accounting for a significant portion of global supply. However, sourcing mica ethically has become a pressing issue. Due to the high demand, there have been reports of child labor and unsafe working conditions in some mica mining regions. This has prompted consumers and businesses to seek transparency in their supply chains, calling for more sustainable and ethically sourced mica.

Creating Radiance and Shine With Cosmetic Mica

Mica powder, known as industrial monosodium glutamate, is widely used. With the continuous development of technology and application market, and some new requirements have been put forward for the quality of mica powder, so synthetic mica powder has been developed. Compared with the natural mica powder processed by natural mica ore, and the synthetic mica powder synthesized by using a variety of raw materials through high temperature reaction and other chemical methods. What are the advantages and differences between them?

- Recently published

X represents large interlayer cations, such as K+, Na+, Ca2+, Ba2+, Rb+, Cs+, etc. Y represents octahedral cations, such as Al3+, Fe2+, Mg2+, Cr3+, Ti4+, Fe3+, etc. Z is mainly Si4+ and Al3+; The ideal ratio of the additional anion (OH)- to (O)2- is 2:10, and (OH)- can be replaced by F- and Cl-. Most mica contain 4% to 5% water. Therefore, although they may be called mica, the chemical composition of different mica may be very different, for the purpose of research, we collectively refer to the minerals with this type of characteristics as mica group minerals.

4. Pour and Create Once you attain your desired hue, pour the resin into your molds or onto your project surface. Experiment with different layering techniques, combining it with other colors or clear resin for dynamic effects.

1. Construction Industry Synthetic rubber powder is widely used in the construction industry in products like adhesives, sealants, and coatings. Its elasticity and water-resistant properties make it an ideal material for insulating and protecting structures from moisture and chemical exposure.

A group of parallel cleavages can be seen in a photograph of biomica under orthogonal polarized (left) and single polarized (right) mirrors.

Conclusion

- natural mica vs synthetic mica

To address these concerns, several companies have begun to prioritize the use of lip safe mica—mica sourced from suppliers that adhere to ethical standards and practices. This shift not only ensures that the mica used in lip products is safe for consumers but also promotes fair labor practices in the communities where mica is mined.

- Random reading

In the world of cosmetics, safety and quality are paramount. One ingredient that has gained significant attention in recent years is mica powder, especially in products intended for lip care and makeup. This article explores what lip-safe mica powder is, its benefits, any potential risks, and how to ensure you are using it safely in your cosmetic formulations.

In short, there are significant differences between natural mica powder and synthetic mica powder in production methods, color and appearance, performance characteristics, application fields, and price and cost. Synthetic mica powder is superior to natural mica powder in terms of high temperature resistance, transparency, electrical insulation, stability and mechanical properties, while natural mica powder has more advantages in resource acquisition, cost and color. When choosing which type of mica powder to use, you can consider the high temperature resistance of the required material, electrical insulation performance, transparency and color requirements, evaluate the mechanical strength and hardness of the required material, consider chemical stability and other different application scenarios and technical requirements to make a reasonable choice.

In addition, lepidolite and ferrolepidolite can also be used as mineral raw materials for extracting lithium.

The Chemical Composition and Structure of Muscovite

X represents large interlayer cations, such as K+, Na+, Ca2+, Ba2+, Rb+, Cs+, etc. Y represents octahedral cations, such as Al3+, Fe2+, Mg2+, Cr3+, Ti4+, Fe3+, etc. Z is mainly Si4+ and Al3+; The ideal ratio of the additional anion (OH)- to (O)2- is 2:10, and (OH)- can be replaced by F- and Cl-. Most mica contain 4% to 5% water. Therefore, although they may be called mica, the chemical composition of different mica may be very different, for the purpose of research, we collectively refer to the minerals with this type of characteristics as mica group minerals.

Mica is a very common rock-forming mineral, widely distributed in crystalline rocks. Its general chemical formula can be expressed as:

- what do you do with mica powder

Natural high quality Muscovite:feel fine, soft lubrication.

X { Y2-3 [Z4O10] (OH)2 }

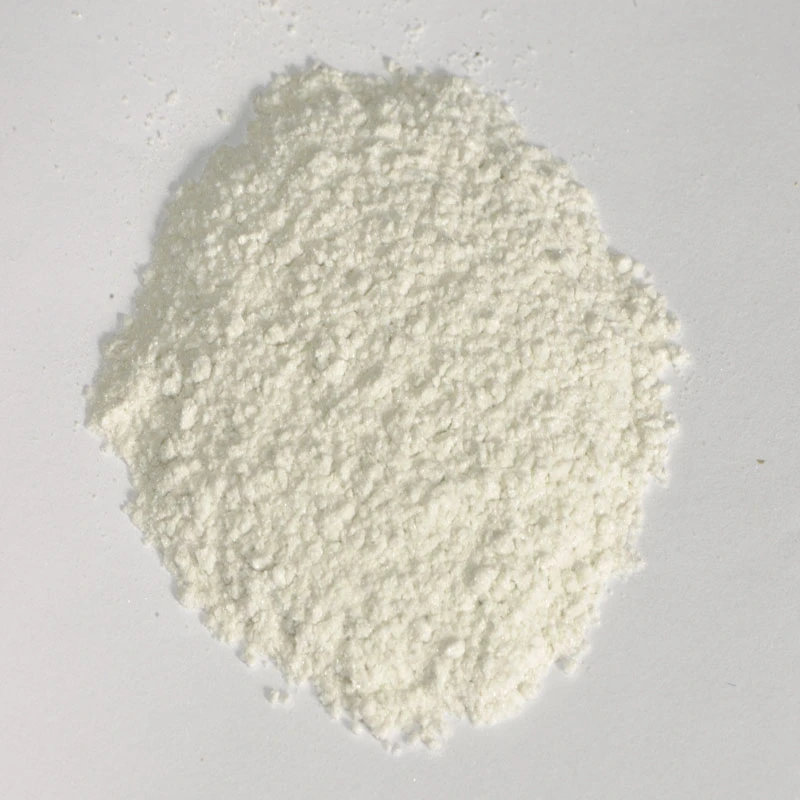

Natural mica powder and synthetic mica powder have differences in production methods, heat resistance and color transparency. As the name suggests, natural mica powder is made from natural mica ore after processing, retaining the original characteristics and composition of the ore. Its main components are SiO2 (about 49%) and Al2O3 (about 30%), while also containing K2O+Na2O (9%-11%) and so on. The synthetic mica powder (such as fluoroglogopicite powder), is the use of a variety of raw materials through high temperature reaction and other chemical methods synthetic, its composition and characteristics can be adjusted and optimized according to the need, the chemical formula is KMg3(AlSi3O10)F2, belongs to the monoclinic crystal system, is a typical layered silicate, relatively single and pure composition. The heat resistance of natural mica powder is generally 500-600℃, and some types, such as phlogopite, can reach 800℃. The heat resistance of synthetic mica powder is more excellent, and it can withstand high temperatures above 1200℃, and the melting point or crystallization temperature is about 1375±5. The transparency of natural mica powder is relatively low, and the color is diverse, including black, yellow, white, gray, green, brown and other colors, and may vary due to different ore types and processing methods. The color of synthetic mica powder is relatively single, usually colorless transparent or white, high whiteness, good optical performance, and high transmittance from ultraviolet to infrared band.

Exploring the Unique Properties and Applications of Epoxy Mica Powder

The mica variety that does not contain iron is colorless in flakes, and the higher the iron content, the darker the color, and the more polychromatic and absorbable it is. According to the different chemical composition and optical characteristics, mica group minerals can be divided into Muscovite subgroup, biotite-phlogopite subgroup and lemica subgroup. The common mica are biotite, phlogopite, Muscovite and so on.

Muscovite, a member of the mica group of minerals, holds a special place in the realm of geology and materials science. Its intricate structure, combined with a suite of unique physical and chemical properties, has made it indispensable in a wide range of industrial applications. This blog delves into the science and significance of muscovite, exploring its composition, formation, and the myriad ways it has shaped our world.

MICA holds a pivotal role in various industries across China, from electronics to construction. As the Chinese economy continues to grow and evolve, so does the demand for this versatile mineral. By addressing the challenges surrounding ethical practices and environmental sustainability, China's MICA industry can unlock significant potential and contribute to a more responsible and innovative future. With its unique properties and wide-ranging applications, MICA is undoubtedly a mineral worth watching in the ever-evolving landscape of China's industrial growth.

Epoxy pearl pigments are often combined with other cosmetic ingredients to create long-lasting formulas that provide a multi-dimensional effect when applied to the skin. The versatility of these pigments allows makeup artists to experiment with different looks and styles, from subtle highlights to bold, dramatic finishes.

Conclusion

In addition, lepidolite and ferrolepidolite can also be used as mineral raw materials for extracting lithium.

- Search

- Links

- mica flakes supplier

- mica cosmetics

- golden colour mica

- is synthetic mica eco friendly

- mica powder in bulk

- automotive paint pigment powder

- pearl pigment for auto paint

- is mica powder safe

- makeup that uses mica

- interior waterproofing paint

- ground mica

- what can you do with mica powder

- epoxy mica

- mica flogopita

- rose gold mica powder

- mica wholesale

- mica powder price

- mica chips for concrete

- is mica powder natural

- mica exporter

- fda approved mica powder

- rock with mica flakes

- mica powder tumblers

- mica powder what is

- what is mica powder used for in makeup

- can you use mica powder in soap

- makeup pigment powder

- mica powder for lip balm

- can mica powder be used in resin

- calcined mica uses

- blue mica flakes

- mica powder cosmetic

- pearlescent mica powder

- mica raw material

- synthetic fluorphlogopite in skin care

- shimmer mica powder

- synthetic mica

- mica material

- mica powder what is it

- gold mica powder for skin

- mica powder for lip gloss

- pearlescent pigment

- what is mica powder for resin

- natural mica powder for cosmetics

- mica safe for skin

- mica dye

- what is synthetic mica

- clear muscovite

- mica powder

- mica for sale

- synthetic fluorphlogopite for skin

- synthetic mica wholesale

- what do you mix with mica powder

- what is mica powder for wax melts

- mica powder white

- shimmer mica

- mica dye powder

- mica powder for paint

- what is mica powder made from

- food safe pearlescent mica

- cosmetic micas

- cosmetic pigment suppliers

- organic mica powder for lip gloss

- mica powder in lip gloss

- glitter mica powder

- muscovite mica flakes

- can i use mica powder for tie dye

- epoxy pigment powder

- mica is made of

- mica pigments for cosmetics

- can you use mica powder in resin

- mica powder uses in cosmetics

- pearl powder for automotive paint

- what is synthetic mica powder

- mica powder for soap

- skin safe mica powder

- mica powder in body butter

- mica for soap making

- golden mica manufacturer

- are mica powders safe

- can you use mica powder in concrete

- phlogopite

- modified plastics

- pearl mica flakes