Как использовать мику в мыловарении?

mica color powder for soap making

In response to these concerns, many brands are reassessing their supply chains. Companies are increasingly opting for mica sourced from mines that adhere to safe working conditions and fair labor practices. Consumers are encouraged to seek brands that demonstrate transparency in their sourcing processes. Labels that indicate responsible sourcing or charity initiatives in mining communities can often provide more confidence.

mica in eyeshadow safe

How to Use Mica Powder A Comprehensive Guide

Modified Plastics Innovations and Applications

Conclusion

- Recently published

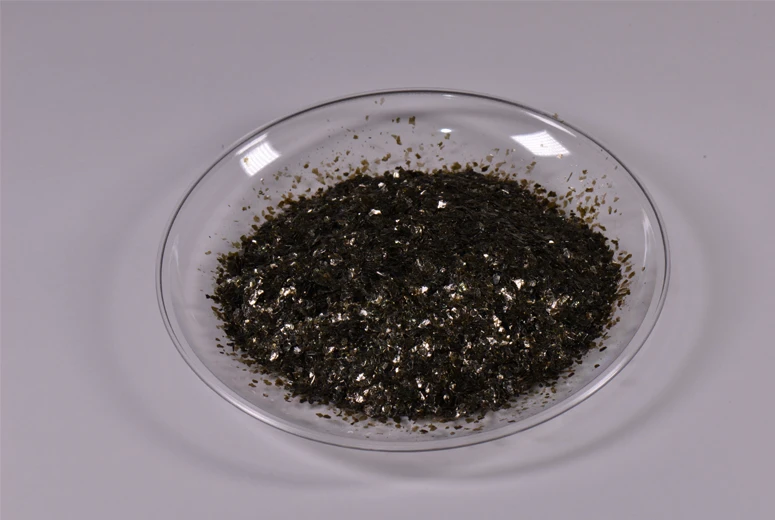

- mica mineral flakes

Advantages of Using Epoxy Mica Powder

The mica variety that does not contain iron is colorless in flakes, and the higher the iron content, the darker the color, and the more polychromatic and absorbable it is. According to the different chemical composition and optical characteristics, mica group minerals can be divided into Muscovite subgroup, biotite-phlogopite subgroup and lemica subgroup. The common mica are biotite, phlogopite, Muscovite and so on.

Natural mica powder and synthetic mica powder also have great differences in electrical insulation, mechanical properties, chemical stability, application range and cost. Natural mica powder has good electrical insulation, but the volume resistivity is lower than that of synthetic mica. Synthetic mica powder has better electrical insulation properties, high volume resistivity and stable dielectric constant, and is suitable for high performance electrical insulation materials. The hardness of natural mica powder is relatively low (2-3), and it has good elasticity and peeling property. The hardness of synthetic mica powder is higher (between 3 and 4), and the tensile strength and compressive strength are better than that of natural mica powder. Natural mica powder is stable in acid-base solution, but it is easy to decompose at high temperature. Synthetic mica powder is stable to acid and base at room temperature, but will be slowly corroded by sulfuric acid above 300℃. Better thermal stability, not easy to release gas. Natural mica powder is widely used in electrical appliances, welding rods, rubber, plastics, paper making, paint and other fields. Synthetic mica powder is mainly used in high-end electrical insulation materials, aviation, aerospace, national defense industry and other high-tech fields. Because synthetic mica powder needs to be produced through complex chemical processes, its production cost is usually higher than that of natural mica powder. Therefore, in the market, the price of synthetic mica powder is often higher than that of natural mica powder. However, with the continuous progress of production technology and the gradual emergence of scale effects, the price of synthetic mica powder is expected to gradually decrease.

When it comes to pigment powders for resin, there are several categories to consider

Later, with the development of science and technology, people gradually realized that mica minerals have high insulation, high temperature resistance, strong acid and alkali resistance, and mica also began to enter building materials, fire, plastics, paper, rubber, pearlite pigments and other industries. These are mainly Muscovite and phlogopite.

Materials Needed

X { Y2-3 [Z4O10] (OH)2 }

The Impact of Mica in the Beauty Industry A Closer Look at Mica Video

Safety and Sustainability Considerations

- Random reading

- heat reflective interior paint

To address these concerns, several companies have begun to prioritize the use of lip safe mica—mica sourced from suppliers that adhere to ethical standards and practices. This shift not only ensures that the mica used in lip products is safe for consumers but also promotes fair labor practices in the communities where mica is mined.

- mica beauty cosmetics eyeshadow

1. Quality of Mica The purity and quality of mica powder can significantly influence its price. High-grade mica, which contains fewer impurities and has superior light-reflecting properties, tends to be more expensive than lower-grade alternatives. Buyers are often willing to pay a premium for high-quality mica powder, particularly in the cosmetics industry where product performance is crucial.

Mica Pearl Powderning Foydalari

- color shift pearl pigment

Huajing mica cosmetic grade mica powder has been loved by customers since it entered the market, and has a general response, excellent quality, stable quality and high reputation.

Synthetic 120 mesh :large particle size, with pearl shining effect.

- does mica powder dissolve in water

The common characteristics of mica group minerals are: layered silicate minerals, monoclinic crystal system, a few trigonal crystal system, the crystals are pseudo-hexagonal columnar, plate and sheet; The aggregate is scaly and foliaceous. It has a set of extremely complete cleavage, along which it is easy to peel into sheets. Therefore, the shape of mica is usually regarded as sheet.

- kinds of mica

In short, there are significant differences between natural mica powder and synthetic mica powder in production methods, color and appearance, performance characteristics, application fields, and price and cost. Synthetic mica powder is superior to natural mica powder in terms of high temperature resistance, transparency, electrical insulation, stability and mechanical properties, while natural mica powder has more advantages in resource acquisition, cost and color. When choosing which type of mica powder to use, you can consider the high temperature resistance of the required material, electrical insulation performance, transparency and color requirements, evaluate the mechanical strength and hardness of the required material, consider chemical stability and other different application scenarios and technical requirements to make a reasonable choice.

In addition, lepidolite and ferrolepidolite can also be used as mineral raw materials for extracting lithium.

- Search

- Links

- muscovite powder

- mica powder

- can i use mica powder to tie dye

- skin safe mica powder

- natural mica vs synthetic mica

- coated mica powder

- synthetic fluorphlogopite vs mica

- can i use mica powder in lip balm

- synthetic fluorphlogopite glitter

- mica makeup products

- what is synthetic mica powder

- is mica powder safe on skin

- is mica powder safe for skin

- what is in mica powder

- mica color powder for soap making

- natural mica

- mica powder tumblers

- skin safe mica

- what is mica dust

- mica powder pearl pigment

- white mica powder for resin

- thermal paint for interior walls

- how do you use mica powder

- adding mica powder to paint

- what can i use instead of mica powder

- muscovite mica flakes

- shimmer mica powder

- what is mica pigment powder used for

- mica powder in body butter

- glitter mica powder for lip gloss

- synthetic fluorphlogopite safe for skin

- can you use mica powder in resin

- mica powder in cosmetics

- lip gloss mica powder

- firedots mica powder

- synthetic fluorphlogopite in cosmetics

- mica powder for epoxy

- gold mica pigment

- adding mica powder to resin

- varieties of mica

- mica material

- ground mica

- is mica powder natural

- mica powder for sale

- calcined mica uses

- mica glitter for candles

- mica powder glitter

- pearlescent pigment uses

- mica flakes bulk

- what is pigment powder used for

- cosmetic micas

- is synthetic mica safe

- mica pigment powder for lip gloss

- mica powder is it safe

- mica powder for wax melts

- pearl mica powder

- gold pigment powder for resin

- can you use mica powder in soap

- mica powder supplier

- metallic mica powders

- synthetic mica eyeshadow

- mica pigments

- heat reflective interior paint

- mica for lip balm

- gold mica powder for cosmetics

- mica beauty cosmetics eyeshadow

- synthetic fluorphlogopite for sale

- china synthetic mica powder

- thermal insulation paint for interior walls

- mica flakes wholesale

- white mica powder for epoxy

- ways to use mica powder

- epoxy resin pigment powder

- phlogopite

- mica powder uses

- mica made of

- lip safe mica

- bulk mica pigment