calcined mica uses

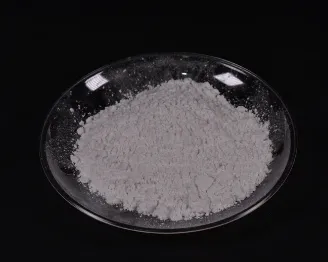

Mica powder, a naturally occurring mineral dust, has gained immense popularity for its versatile app...

thermal paint for interior walls_thermal paint for interior walls

Mica powder, a naturally occurring mineral dust, has gained immense popularity for its versatile app...

thermal paint for interior walls_thermal paint for interior walls

Beyond their ability to create eye-catching shine, mica pigments offer several other benefits in cosmetics. They are non-toxic, gentle on the skin, and non-comedogenic, meaning they do not clog pores. This makes mica an ideal choice for individuals with sensitive or acne-prone skin. Additionally, mica has natural UV-filtering properties, which can offer some level of protection against harmful sun exposure.

With a growing demand for mica flakes, finding a reputable supplier is essential. Whether you’re purchasing for cosmetic applications or industrial use, it’s important to choose a mica flakes supplier that can guarantee consistent quality and reliability. Some suppliers offer mica flakes sourced from natural deposits, while others may offer synthetic mica options, which are often used when higher purity or specific attributes are needed.

In terms of authoritativeness, Chinese companies have developed comprehensive quality control systems to ensure that the mica produced meets international standards. This commitment to quality is recognized worldwide, establishing Chinese mica as a trustworthy choice for industries ranging from cosmetics to construction. The rigorous testing and certification processes that Chinese mica undergoes further bolster the country's reputation as a reliable source of high-quality mica.

2. Avoid Harmful Additives Look for products that are free from parabens, sulfates, and other harmful chemicals. This can help reduce any potential irritation.

Featured products:

The mica variety that does not contain iron is colorless in flakes, and the higher the iron content, the darker the color, and the more polychromatic and absorbable it is. According to the different chemical composition and optical characteristics, mica group minerals can be divided into Muscovite subgroup, biotite-phlogopite subgroup and lemica subgroup. The common mica are biotite, phlogopite, Muscovite and so on.

The mica powder of HUAJING has the advantage of extremely narrow particle size, and the particle size specifications are complete, such as: 2000 mesh, 1250 mesh, 800 mesh, 400 mesh, 120 mesh, etc. The skin feeling is exquisite.

In the construction sector, mica's aesthetic appeal and robust structural attributes make it a sought-after material. Mica factories produce products that are integral to enhancing the durability and visual appeal of buildings. Used extensively in paint, drywall, and plaster, mica enhances the decorative elements while providing a layer of thermal insulation. This dual function not only elevates architectural aesthetics but also contributes to energy efficiency, exemplifying the multifaceted applications of mica products crafted by these specialized factories.

The common characteristics of mica group minerals are: layered silicate minerals, monoclinic crystal system, a few trigonal crystal system, the crystals are pseudo-hexagonal columnar, plate and sheet; The aggregate is scaly and foliaceous. It has a set of extremely complete cleavage, along which it is easy to peel into sheets. Therefore, the shape of mica is usually regarded as sheet.

Natural high quality Muscovite:feel fine, soft lubrication.

For example, the safe operation of high-speed rail cannot be separated from the escort of mica products.

The use of metallic mica powder in epoxy applications showcases the intersection of art and functionality. Its wide color range, aesthetic versatility, and ease of use make it a favored option among crafters and artisans looking to create stunning projects. Whether it’s used for crafting jewelry, embellishing furniture, or producing artistic resin pieces, metallic mica powder offers an elegant solution that enhances the visual appeal of epoxy creations.

Take pearlescent pigments as an example, pearlescent pigments are a class of pigments with pearl luster, which are deposited on the substrate (generally natural mica, synthetic mica, glass sheet and other sheet-like materials) above a layer or alternately deposited multiple layers of metal oxides or non-metallic oxides and formed a flat sandwich body with a structure similar to sandwich. Due to the difference in refractive index between the substrate and the oxide deposited on its surface and each oxide, when the light shines on the surface of the pearlescent pigment, the incident light will be refracted and reflected at the interface of each layer of the pearlescent pigment, and the color of the pearlescent pigment that people see is the result of the superposition of light after multiple refractions and reflections of the light, that is, the interference phenomenon of light.

Later, with the development of science and technology, people gradually realized that mica minerals have high insulation, high temperature resistance, strong acid and alkali resistance, and mica also began to enter building materials, fire, plastics, paper, rubber, pearlite pigments and other industries. These are mainly Muscovite and phlogopite.

In addition, lepidolite and ferrolepidolite can also be used as mineral raw materials for extracting lithium.

Mica operations are integral to various industries, providing essential materials that contribute to technological advancement and everyday products. However, the challenges associated with environmental impact and ethical sourcing cannot be overlooked. By transitioning towards sustainable practices and ensuring ethical labor conditions, the mica industry can thrive while addressing the concerns that have long plagued it. The future of mica operations lies in the hands of all stakeholders willing to prioritize sustainability and ethics, ensuring that this valuable resource can be harnessed responsibly for generations to come.

The mica industry is undergoing profound changes. With the help of emerging industries, the mica industry will be a large market of more than 10 billion.

For example, the safe operation of high-speed rail cannot be separated from the escort of mica products.

Take pearlescent pigments as an example, pearlescent pigments are a class of pigments with pearl luster, which are deposited on the substrate (generally natural mica, synthetic mica, glass sheet and other sheet-like materials) above a layer or alternately deposited multiple layers of metal oxides or non-metallic oxides and formed a flat sandwich body with a structure similar to sandwich. Due to the difference in refractive index between the substrate and the oxide deposited on its surface and each oxide, when the light shines on the surface of the pearlescent pigment, the incident light will be refracted and reflected at the interface of each layer of the pearlescent pigment, and the color of the pearlescent pigment that people see is the result of the superposition of light after multiple refractions and reflections of the light, that is, the interference phenomenon of light.

2. Inorganic Pigments Often made from minerals, inorganic pigments are renowned for their durability and lightfastness. They provide excellent coverage and are less prone to fading, making them suitable for exterior applications.

Natural mica powder and synthetic mica powder have differences in production methods, heat resistance and color transparency. As the name suggests, natural mica powder is made from natural mica ore after processing, retaining the original characteristics and composition of the ore. Its main components are SiO2 (about 49%) and Al2O3 (about 30%), while also containing K2O+Na2O (9%-11%) and so on. The synthetic mica powder (such as fluoroglogopicite powder), is the use of a variety of raw materials through high temperature reaction and other chemical methods synthetic, its composition and characteristics can be adjusted and optimized according to the need, the chemical formula is KMg3(AlSi3O10)F2, belongs to the monoclinic crystal system, is a typical layered silicate, relatively single and pure composition. The heat resistance of natural mica powder is generally 500-600℃, and some types, such as phlogopite, can reach 800℃. The heat resistance of synthetic mica powder is more excellent, and it can withstand high temperatures above 1200℃, and the melting point or crystallization temperature is about 1375±5. The transparency of natural mica powder is relatively low, and the color is diverse, including black, yellow, white, gray, green, brown and other colors, and may vary due to different ore types and processing methods. The color of synthetic mica powder is relatively single, usually colorless transparent or white, high whiteness, good optical performance, and high transmittance from ultraviolet to infrared band.

3. Plastics and Composites Flogopita is added to plastics and composites to enhance their mechanical strength and thermal stability. This addition helps improve the overall performance of these materials, making them suitable for use in more demanding applications, such as electronics and construction.