- Basements and Foundations Preventing water seepage in areas that are prone to flooding or dampness is crucial. Waterproof paint can protect basement walls and floors, ensuring a dry and comfortable environment.

In short, there are significant differences between natural mica powder and synthetic mica powder in production methods, color and appearance, performance characteristics, application fields, and price and cost. Synthetic mica powder is superior to natural mica powder in terms of high temperature resistance, transparency, electrical insulation, stability and mechanical properties, while natural mica powder has more advantages in resource acquisition, cost and color. When choosing which type of mica powder to use, you can consider the high temperature resistance of the required material, electrical insulation performance, transparency and color requirements, evaluate the mechanical strength and hardness of the required material, consider chemical stability and other different application scenarios and technical requirements to make a reasonable choice.

While mica pearlescent pigments offer numerous benefits, they are not without challenges. Maintaining consistency in particle size and color can be challenging during manufacturing. Technological advancements are being made to refine production processes, ensuring high-quality outputs that meet industrial specifications.

X represents large interlayer cations, such as K+, Na+, Ca2+, Ba2+, Rb+, Cs+, etc. Y represents octahedral cations, such as Al3+, Fe2+, Mg2+, Cr3+, Ti4+, Fe3+, etc. Z is mainly Si4+ and Al3+; The ideal ratio of the additional anion (OH)- to (O)2- is 2:10, and (OH)- can be replaced by F- and Cl-. Most mica contain 4% to 5% water. Therefore, although they may be called mica, the chemical composition of different mica may be very different, for the purpose of research, we collectively refer to the minerals with this type of characteristics as mica group minerals.

White mica, also known as muscovite, is a fascinating mineral that captivates geologists, artists, and collectors alike. With its unique physical properties, aesthetic appeal, and cultural significance, white mica stands as a testament to the beauty and complexity of the natural world. This article explores the origins, characteristics, uses, and significance of white mica, highlighting why it continues to charm so many.

The automotive industry also benefits from this amazing pigment. Pearl white finishes on cars are highly sought after for their aesthetic appeal, offering a luxurious touch that stands out. Manufacturers often employ pearl white pigments in the paint formulations to achieve that coveted iridescent effect, captivating car enthusiasts and consumers alike.

* Cosmetics Muscovite mica is commonly used in cosmetics and personal care products, such as makeup, lotions, and creams, due to its shimmering properties and ability to improve texture.

The mica variety that does not contain iron is colorless in flakes, and the higher the iron content, the darker the color, and the more polychromatic and absorbable it is. According to the different chemical composition and optical characteristics, mica group minerals can be divided into Muscovite subgroup, biotite-phlogopite subgroup and lemica subgroup. The common mica are biotite, phlogopite, Muscovite and so on.

For example, the safe operation of high-speed rail cannot be separated from the escort of mica products.

Mica is a naturally occurring mineral that is ground down to a fine powder. When treated with metallic oxides, it takes on a stunning range of colors and a lustrous finish. This process makes mica powder highly versatile, enabling it to mimic the appearance of metals, gemstones, and other materials. The resulting metallic mica powder adds a beautiful shimmer and depth to epoxy resin, resulting in eye-catching effects that can elevate any project.

Electrical Insulation: Like other micas, phlogopite offers excellent dielectric strength, making it ideal for use in capacitors, transformers, and other electrical components.

Take pearlescent pigments as an example, pearlescent pigments are a class of pigments with pearl luster, which are deposited on the substrate (generally natural mica, synthetic mica, glass sheet and other sheet-like materials) above a layer or alternately deposited multiple layers of metal oxides or non-metallic oxides and formed a flat sandwich body with a structure similar to sandwich. Due to the difference in refractive index between the substrate and the oxide deposited on its surface and each oxide, when the light shines on the surface of the pearlescent pigment, the incident light will be refracted and reflected at the interface of each layer of the pearlescent pigment, and the color of the pearlescent pigment that people see is the result of the superposition of light after multiple refractions and reflections of the light, that is, the interference phenomenon of light.

Featured products:

Featured products:

One of the main advantages of incorporating gold mica powder into resin projects is its sheer versatility. Unlike traditional pigments, mica powders are highly concentrated, meaning only a small amount is needed to achieve vibrant results. This concentration allows artists to control the intensity of the color, whether they desire a subtle shimmer or a more pronounced metallic finish.

Later, with the development of science and technology, people gradually realized that mica minerals have high insulation, high temperature resistance, strong acid and alkali resistance, and mica also began to enter building materials, fire, plastics, paper, rubber, pearlite pigments and other industries. These are mainly Muscovite and phlogopite.

Layer upon layer of mica

In short, there are significant differences between natural mica powder and synthetic mica powder in production methods, color and appearance, performance characteristics, application fields, and price and cost. Synthetic mica powder is superior to natural mica powder in terms of high temperature resistance, transparency, electrical insulation, stability and mechanical properties, while natural mica powder has more advantages in resource acquisition, cost and color. When choosing which type of mica powder to use, you can consider the high temperature resistance of the required material, electrical insulation performance, transparency and color requirements, evaluate the mechanical strength and hardness of the required material, consider chemical stability and other different application scenarios and technical requirements to make a reasonable choice.

The Science Behind the Shine

Synthetic matte 2000 mesh:fine skin, matte effect.

One of the most popular uses of mica powder is in the creation of cosmetics. Its fine texture and natural shimmer make it an ideal ingredient for products like eyeshadows, highlighters, and blushes.

Huajing mica cosmetic grade mica powder has been loved by customers since it entered the market, and has a general response, excellent quality, stable quality and high reputation.

Later, with the development of science and technology, people gradually realized that mica minerals have high insulation, high temperature resistance, strong acid and alkali resistance, and mica also began to enter building materials, fire, plastics, paper, rubber, pearlite pigments and other industries. These are mainly Muscovite and phlogopite.

Consumers are increasingly becoming aware of the implications of their purchases, prompting a shift towards brands that prioritize ethical sourcing. This trend not only fosters responsible mining practices but also encourages innovation in the formulation of cosmetics, leading to the exploration of alternative ingredients and synthetic mica.

What are the uses of mica

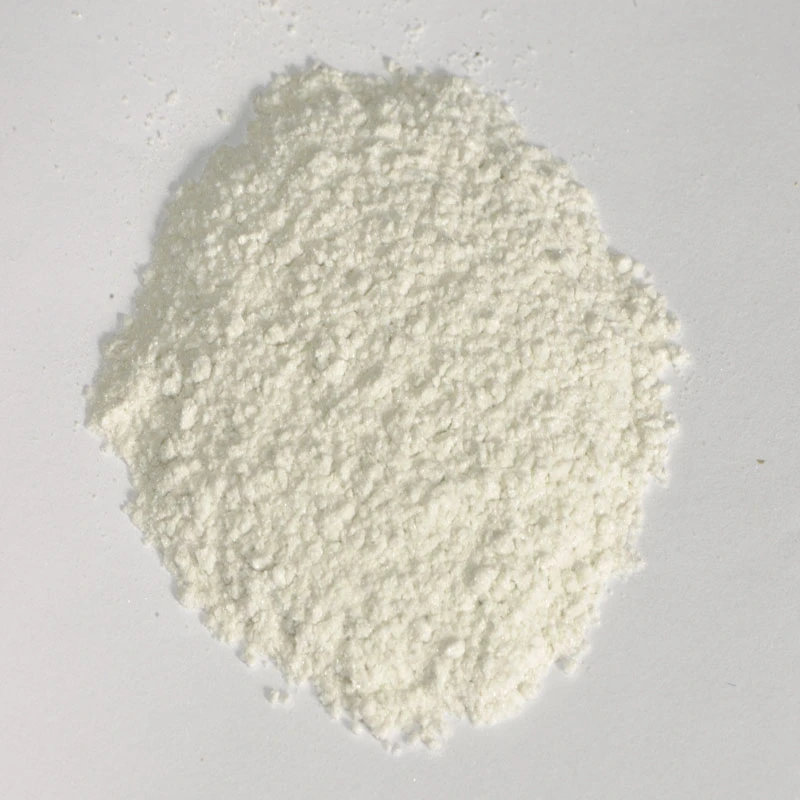

Mica powder, known as industrial monosodium glutamate, is widely used. With the continuous development of technology and application market, and some new requirements have been put forward for the quality of mica powder, so synthetic mica powder has been developed. Compared with the natural mica powder processed by natural mica ore, and the synthetic mica powder synthesized by using a variety of raw materials through high temperature reaction and other chemical methods. What are the advantages and differences between them?