Mar . 04, 2025 10:12

Back to list

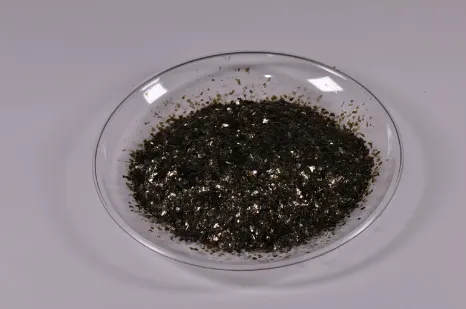

40-D Mica Powder

In the realm of crafting and home fragrance, wax melts have become a preferred choice for their versatility and ease of use. As you navigate the creation of wax melts for personal use or business, a common inquiry arises can mica powder be used in wax melts? Drawing from extensive experience and professional knowledge, the integration of mica powder into wax melts presents both opportunities and challenges, impacting the visual appeal and performance of your final product.

Additionally, safety remains a paramount concern. While mica itself is generally regarded as safe, care must be taken to ensure that the powder is specifically approved for use in products that produce heat when in contact with a warmer. Mica powders designed for cosmetic or soap use may not always undergo the same testing for high-temperature applications. Therefore, sourcing mica from reputable suppliers who guarantee its suitability for fragrance-related applications is vital in maintaining the trust of your consumers. To foster trustworthiness and credibility with your audience, transparency in your product descriptions is essential. If you choose to use mica in your wax melts, providing clear information about its purpose, safety, and effect on the product will enhance consumer confidence. Detailing your testing process and any precautions taken can further bolster your reputation for conscientious and responsible crafting. In summary, while incorporating mica powder into wax melts can undeniably enhance visual appeal, it requires a careful balance of expertise and attention to detail to ensure the product remains functional, safe, and aesthetically pleasing. By thoroughly testing different wax and mica combinations and prioritizing transparency and safety, creators can leverage mica's decorative potential without compromising the quality and integrity of their wax melts. In doing so, they can offer a unique, visually stunning product that meets both aesthetic and functional demands, distinguishing themselves in a competitive market.

Additionally, safety remains a paramount concern. While mica itself is generally regarded as safe, care must be taken to ensure that the powder is specifically approved for use in products that produce heat when in contact with a warmer. Mica powders designed for cosmetic or soap use may not always undergo the same testing for high-temperature applications. Therefore, sourcing mica from reputable suppliers who guarantee its suitability for fragrance-related applications is vital in maintaining the trust of your consumers. To foster trustworthiness and credibility with your audience, transparency in your product descriptions is essential. If you choose to use mica in your wax melts, providing clear information about its purpose, safety, and effect on the product will enhance consumer confidence. Detailing your testing process and any precautions taken can further bolster your reputation for conscientious and responsible crafting. In summary, while incorporating mica powder into wax melts can undeniably enhance visual appeal, it requires a careful balance of expertise and attention to detail to ensure the product remains functional, safe, and aesthetically pleasing. By thoroughly testing different wax and mica combinations and prioritizing transparency and safety, creators can leverage mica's decorative potential without compromising the quality and integrity of their wax melts. In doing so, they can offer a unique, visually stunning product that meets both aesthetic and functional demands, distinguishing themselves in a competitive market.

Prev:

Next:

Latest news

-

Mica Pearlescent: The Secret to Stunning Cosmetics & MakeupNewsJun.25,2025

-

Matte Mica Powder: The Ultimate Cosmetic Enhancement for Makeup ArtistryNewsJun.25,2025

-

Insulating Paint for Interior Walls: The Ultimate Solution for Energy EfficiencyNewsJun.25,2025

-

Crafting & DIY Projects with Organic Mica Powder: Elevate Your CreationsNewsJun.25,2025

-

Craft & DIY Projects with Mica Powder For SoapNewsJun.25,2025

-

Cosmetic & Makeup Applications of Natural Mica PowdersNewsJun.25,2025

Products categories